WhatsApp: +8615665767071 Email: info@eworldmachine.com

Views: 56 Author: Site Editor Publish Time: 2019-07-04 Origin: Site

For example.If the original glass is small and the shape of glass you want to get is not regular, such as glass applied in watch and mirror,I recommend a small automatic glass cutting machine.The more the number of cutting head, the faster the processing speed.The same principle,The more the number of cutting head, the higher the machine cost.

1.Manual or semi-automatic big glass cutting machine. This is a economical machine but it only can cut out glass with regular shape.Glass can be cut efficiently and precisely.Cut only straight lines Semi-automatic glass cutters are used to cut glasses into small pieces. The machine can only cut straight lines, perfect for those who cut the building glasses. Their dual-bridge construction ensures high accuracy and high efficiency.

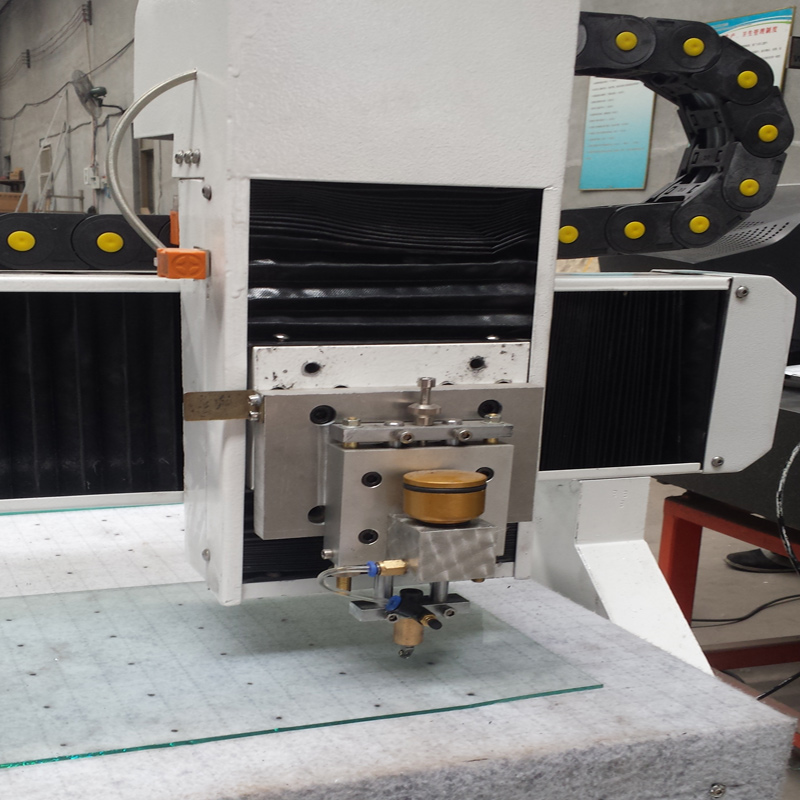

2. Automatic big glass cutting machine.This machine can controlled by PLC computer so it can make glass of irregular or regular shape.Glass cutting of any shape is high-precision ·Graphical input for AUTO CAD design,Art glass, optical glass, mobile phone panels and automotive mirror industry can be provided Air-floating and suction table function

Automatic lubrication system High precision, fast speed, easy operation, wide range of applications.

3.Integrated glass loading cutting and breaking machine. Promotion version of 2 and this machine can load, cut and break glass with high precision.

Eworld is a reliable manufacturer, and we only provide a suitable quotation.We strives to find a balance between quality and price, so that customers can buy the best machine and we can win-win.Eworld Machine provides full set services and high-quality but low-price products.We are always looking for long term cooperaion, not one time deal.

Every week i share some tips about glass processing machine, CNC equipment and windows equipment. Welcome to talk with me or suggestion.