WhatsApp: +8615665767071 Email: info@eworldmachine.com

WD1630

Eworld

8475291900

| Availability: | |

|---|---|

| Quantity: | |

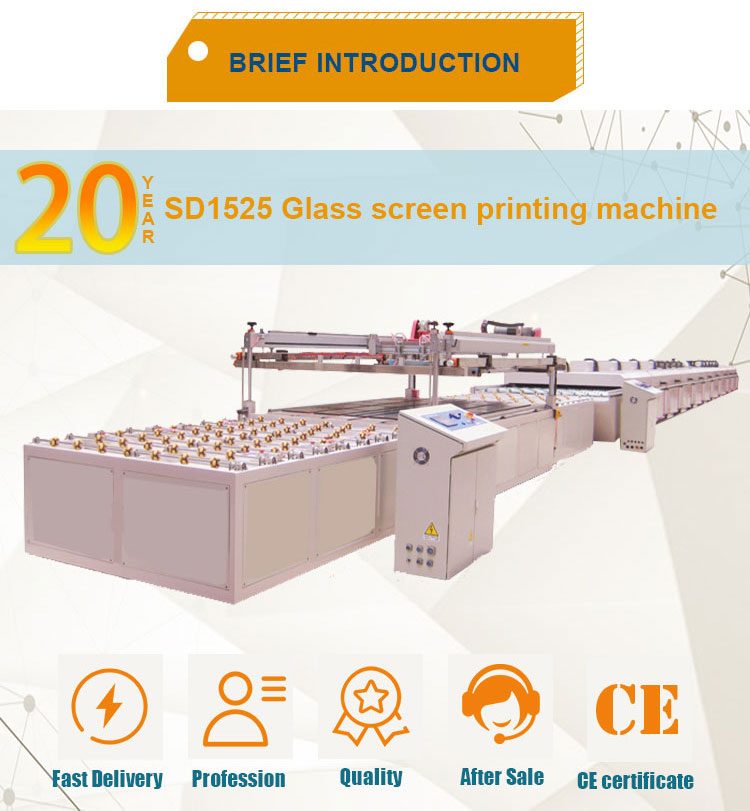

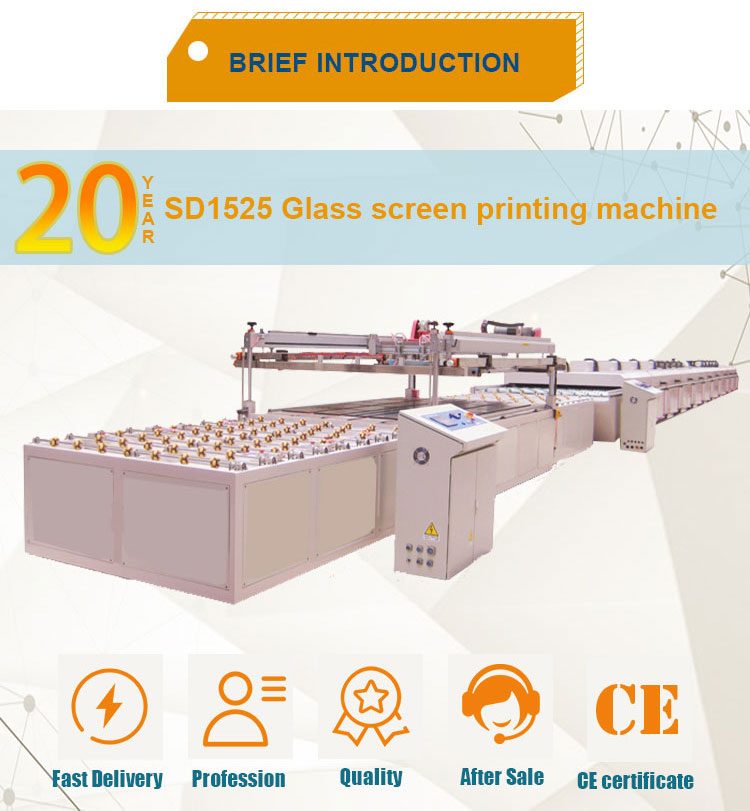

Automatic PET Film Panel Paper Box Screen Printing Machine

As a renowned Manufacturer, Supplier and Exporter of Glass Printing Machine, we bring you a wide range of immaculate quality. Our skilled professionals use only high-grade raw materials to ensure that our product meets the highest quality standards. The machine on offer is the perfect solution for commercial application in glass printing. The features such as longer service life and high durability make it an interesting proposition. To further add to the allure, it is available in customized specifications at cost-effective prices.

Application : Auto glass, furniture glass, the various sectors of mosaic gold glass of home appliances, KT board and high precision screen printing of flat hard panel.

General introduction

Screen printing machine is a machine use printing technique to make colorful glass. It is widely used in decorative glass, architectural glass, furniture glass, appliance glass etc.

Working Principle

Screen printing machine uses a woven mesh to support an ink-blocking stencil to receive a desired image. The attached stencil forms open areas of mesh that transfer ink or other printable materials which can be pressed through the mesh as a sharp-edged image onto a substrate. A fill blade or squeegee is moved across the screen stencil, forcing or pumping ink into the mesh openings for transfer by capillary action during the squeegee stroke. Basically, it is the process of using a stencil to apply ink onto another material such as glass, ceramics, paper etc that can keep the image onto its surface.

Application:

Auto glass, furniture glass, the various sectors of mosaic gold glass of home appliances, KT board and high precision screen printing of flat hard panel.

Main Features:

(1)PLC programmable control, Human-machine operation interface.

(2)Iron parts: Printing Girder, Machine head, Screen Printing clamp.

(3)Variable frequency motor drive printing knife rest, quadrate linear precision guide rail, adjusts the speed and stroke independently.

(4)Variable frequency gear Reducer Motor drive screen printing plate lift up and down and move stably, high precision.

(5)There are high accurate grinding hardness platform and adsorption hole on it; It is equipped with precision adjusting handle and accurate chromatography.

(6)It is equipped with screen space regulating device around screen printing arm lock and adjust conveniently.

(7)The angle of printing and ink-return can be adjustable. Install horizontal device right and left.

(8)Loading panel automatically, Preliminary positioning,precision positioning, printing, discharge panel

(9)Adopting excellent imported silicone rubble roller, convey stably; it has character of low noise, high speed and long life.

(10)Adopt line type and multi point type for printing positioning and make sure printing positioning of all kinds of shapes flat glass.

(11)Installing automatic pressure compensation system is to make sure the printing precision.

Technical Parameters:

Max glass size 1600*3000mm

Min glass size500*700

Max screen glass 2200*3780mm

Table size 1900*3400mm

Thickness available 20mm

Power 12 kw

Weight 5 ton

Overall size 10600*2200*1300mm

After-sales service:

The way of after-sales service:

We can guide the technical staff to maintain, operate and technical training by email, video, telephone. If buyer need seller's technical staff comes to buyer's country to maintain machines, the buyer needs to pay all the fees of seller's technical staff in buyer's country.

The content of after-sales service:

When the device goes wrong and receive email, fax, telephone, we will direct buyer's technical staff to maintain machines by email, telephone, and video. If buyer need seller's technical staff comes to buyer's country to solve the problem, the buyer needs to pay all the fees of seller's technical staff in buyer's country.

After-sales service is not only including the maintenance of machine, but also including a whole set of printing technology, printing information and equipment project.

Maintain printing equipment and accessory equipment and improve old equipment.

Design and Customize dedicated product printing equipment and accessory equipment.

When buyer needs some machine parts during one year, seller can supply the machine parts for free, but buyer needs to pay freight.

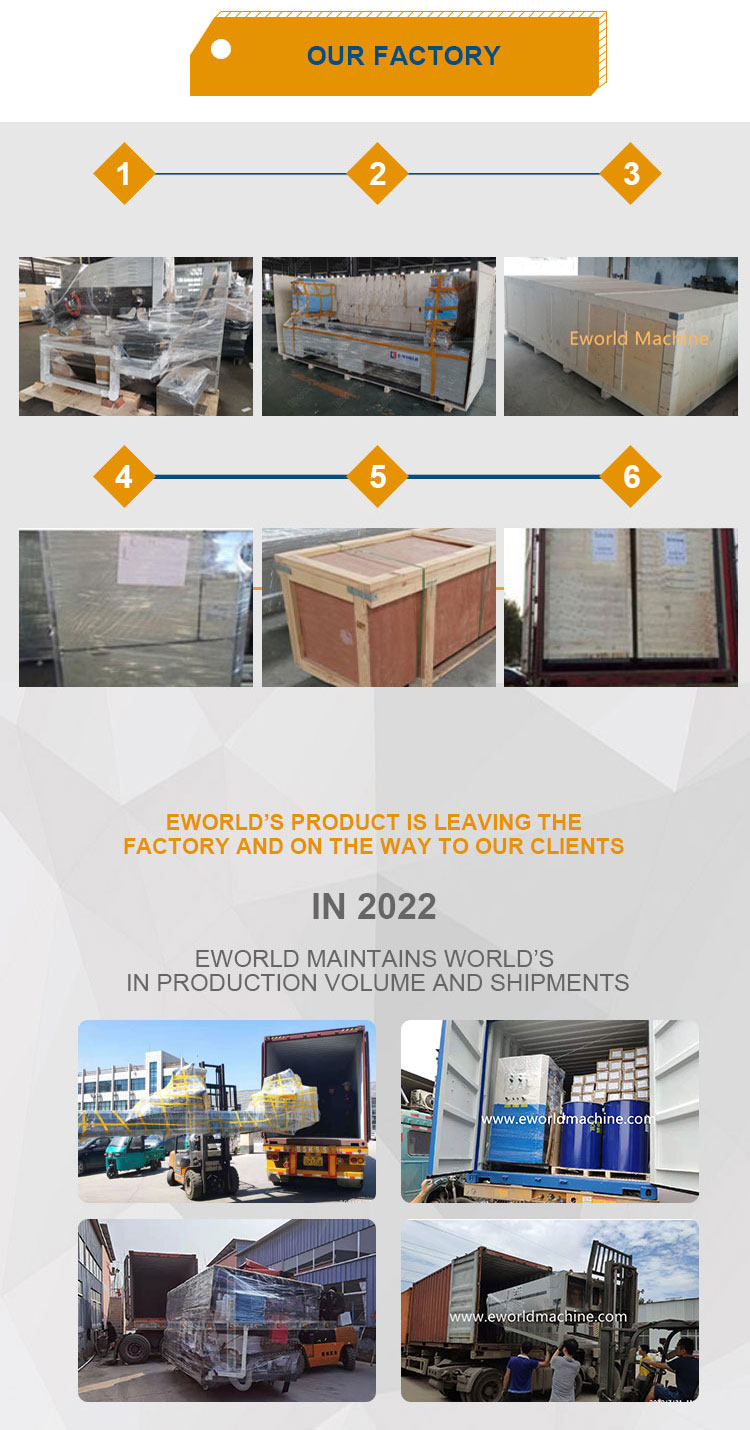

*20years factory production experience*3 years machine warranty

*156 exported country experience

*20000 square meters Glass machine&upvc windows machine factory

*Shandong Eworld Machine Co., Ltd.

Shandong Eworld Machine Co., Ltd. is one of the famous and big manufacturers of glass equipment, windows equipment, CNC equipment.

Since its inception in 2002, and after many years of development and growth, the company is now playing a leading role in glass machinery and windows door machine inChina Eworld group has 2 factories, which are located in Jinan City. Advanced products, exquisite techniques, solid working, and cordial services

About glass deep processing machines, we are professional and have full set certificates.For every glass cutting machine, we have

serious quality control for every machine and every parts before it leaves our factory.

We went to many exhibitions in China to expand our reputation.

Welcome to visit our factory!If you have plan to come to China and see our machines, please contact us at least 15 days in advance

then we can arrange our

schedule and arrange to treat you.

No matter which transport method you choose, we will pick up you.

If you have any questions, please feel free to contact us.

24*7, we always be here !

FAQ

Question:Are you manufacture?

Answer:Yes,we are the professional manufacture which have more than 5 workshops.

Question: How about the service ?

Answer:

1).reply it at once if from Ali-trademanager,if by email,it reply it within 12 hour

2).deliver max. days within 15 days

3).24 hours for after -sale serive

4).more than 12 years experience in this kind machine field

5).fluent english ,communication barrier free

Question:What’s the guarantee ?

Answer:

1).Our guarantee for 18 months.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).2 year quality guaranty for the machine (excluding the consumables)

5).We will provide the consumable parts at an agency price

6).24 hours on line service each day, free technical support.

Q: Do you provide equipment operation training?

Answer:Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. Allof our engineers have passport.

Question:if our price is higher than another company or factories ?

Answer:please check, what is is the different of the machine parts ,service and guarantee,especially the machine inner electric parts,sometimes, if machines have breakdown, the most reason is the machine inner electric parts problem, but we use the famous andreliable parts for the machines inside.

Question:How long is the delivery time ?

Answer:For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients specific requirements, it would be 15 to 30 days.

Question: What is the payment ?

Answer:Any payment method you want,such as L/C,T/T,D/P,West-union and so on.

Automatic PET Film Panel Paper Box Screen Printing Machine

As a renowned Manufacturer, Supplier and Exporter of Glass Printing Machine, we bring you a wide range of immaculate quality. Our skilled professionals use only high-grade raw materials to ensure that our product meets the highest quality standards. The machine on offer is the perfect solution for commercial application in glass printing. The features such as longer service life and high durability make it an interesting proposition. To further add to the allure, it is available in customized specifications at cost-effective prices.

Application : Auto glass, furniture glass, the various sectors of mosaic gold glass of home appliances, KT board and high precision screen printing of flat hard panel.

General introduction

Screen printing machine is a machine use printing technique to make colorful glass. It is widely used in decorative glass, architectural glass, furniture glass, appliance glass etc.

Working Principle

Screen printing machine uses a woven mesh to support an ink-blocking stencil to receive a desired image. The attached stencil forms open areas of mesh that transfer ink or other printable materials which can be pressed through the mesh as a sharp-edged image onto a substrate. A fill blade or squeegee is moved across the screen stencil, forcing or pumping ink into the mesh openings for transfer by capillary action during the squeegee stroke. Basically, it is the process of using a stencil to apply ink onto another material such as glass, ceramics, paper etc that can keep the image onto its surface.

Application:

Auto glass, furniture glass, the various sectors of mosaic gold glass of home appliances, KT board and high precision screen printing of flat hard panel.

Main Features:

(1)PLC programmable control, Human-machine operation interface.

(2)Iron parts: Printing Girder, Machine head, Screen Printing clamp.

(3)Variable frequency motor drive printing knife rest, quadrate linear precision guide rail, adjusts the speed and stroke independently.

(4)Variable frequency gear Reducer Motor drive screen printing plate lift up and down and move stably, high precision.

(5)There are high accurate grinding hardness platform and adsorption hole on it; It is equipped with precision adjusting handle and accurate chromatography.

(6)It is equipped with screen space regulating device around screen printing arm lock and adjust conveniently.

(7)The angle of printing and ink-return can be adjustable. Install horizontal device right and left.

(8)Loading panel automatically, Preliminary positioning,precision positioning, printing, discharge panel

(9)Adopting excellent imported silicone rubble roller, convey stably; it has character of low noise, high speed and long life.

(10)Adopt line type and multi point type for printing positioning and make sure printing positioning of all kinds of shapes flat glass.

(11)Installing automatic pressure compensation system is to make sure the printing precision.

Technical Parameters:

Max glass size 1600*3000mm

Min glass size500*700

Max screen glass 2200*3780mm

Table size 1900*3400mm

Thickness available 20mm

Power 12 kw

Weight 5 ton

Overall size 10600*2200*1300mm

After-sales service:

The way of after-sales service:

We can guide the technical staff to maintain, operate and technical training by email, video, telephone. If buyer need seller's technical staff comes to buyer's country to maintain machines, the buyer needs to pay all the fees of seller's technical staff in buyer's country.

The content of after-sales service:

When the device goes wrong and receive email, fax, telephone, we will direct buyer's technical staff to maintain machines by email, telephone, and video. If buyer need seller's technical staff comes to buyer's country to solve the problem, the buyer needs to pay all the fees of seller's technical staff in buyer's country.

After-sales service is not only including the maintenance of machine, but also including a whole set of printing technology, printing information and equipment project.

Maintain printing equipment and accessory equipment and improve old equipment.

Design and Customize dedicated product printing equipment and accessory equipment.

When buyer needs some machine parts during one year, seller can supply the machine parts for free, but buyer needs to pay freight.

*20years factory production experience*3 years machine warranty

*156 exported country experience

*20000 square meters Glass machine&upvc windows machine factory

*Shandong Eworld Machine Co., Ltd.

Shandong Eworld Machine Co., Ltd. is one of the famous and big manufacturers of glass equipment, windows equipment, CNC equipment.

Since its inception in 2002, and after many years of development and growth, the company is now playing a leading role in glass machinery and windows door machine inChina Eworld group has 2 factories, which are located in Jinan City. Advanced products, exquisite techniques, solid working, and cordial services

About glass deep processing machines, we are professional and have full set certificates.For every glass cutting machine, we have

serious quality control for every machine and every parts before it leaves our factory.

We went to many exhibitions in China to expand our reputation.

Welcome to visit our factory!If you have plan to come to China and see our machines, please contact us at least 15 days in advance

then we can arrange our

schedule and arrange to treat you.

No matter which transport method you choose, we will pick up you.

If you have any questions, please feel free to contact us.

24*7, we always be here !

FAQ

Question:Are you manufacture?

Answer:Yes,we are the professional manufacture which have more than 5 workshops.

Question: How about the service ?

Answer:

1).reply it at once if from Ali-trademanager,if by email,it reply it within 12 hour

2).deliver max. days within 15 days

3).24 hours for after -sale serive

4).more than 12 years experience in this kind machine field

5).fluent english ,communication barrier free

Question:What’s the guarantee ?

Answer:

1).Our guarantee for 18 months.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).2 year quality guaranty for the machine (excluding the consumables)

5).We will provide the consumable parts at an agency price

6).24 hours on line service each day, free technical support.

Q: Do you provide equipment operation training?

Answer:Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. Allof our engineers have passport.

Question:if our price is higher than another company or factories ?

Answer:please check, what is is the different of the machine parts ,service and guarantee,especially the machine inner electric parts,sometimes, if machines have breakdown, the most reason is the machine inner electric parts problem, but we use the famous andreliable parts for the machines inside.

Question:How long is the delivery time ?

Answer:For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients specific requirements, it would be 15 to 30 days.

Question: What is the payment ?

Answer:Any payment method you want,such as L/C,T/T,D/P,West-union and so on.

content is empty!