WhatsApp: +8615665767071 Email: info@eworldmachine.com

SD3826

Eworld

| Availability: | |

|---|---|

| Quantity: | |

Overview

Quick Details

Applicable Industries: Manufacturing Plant

After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location: None

Showroom Location: None

Condition: New

Machine Type: Glass Cutting Machine

Production Capacity: 10sets/month

Place of Origin: Shandong, China

Brand Name: Eworld Machine

Voltage: As request

Power: 21kw

Dimension(L*W*H): 4500*3800*900mm

Certification: ce

Warranty: More than 5 years

After-sales Service Provided: Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

Key Selling Points: Easy to Operate

Glass Thickness: 1-40mm

Machinery Test Report: Provided

Video outgoing inspection: Provided

Marketing Type: New Product 2020

Warranty of core components: 1 Year

Core Components: Pressure vessel, Motor, Bearing, Gear, PLC, Pump, Engine, Gearbox

Name: Glass Cutting Table

Usage: Cut laminated and thick glass

Function: Multifunction

Color: Customers' Request

Seaport: Qingdao Port

Material: Stainless Steel

Model: Eworld

Service: Full set after-sale services

Glass thickness: 3-25mm

Style: High automatic

Supply Ability

Supply Ability: 10 Set/Sets per Month

Packaging & Delivery

Packaging Details: Wooden case Seaworthy package

Port: Qingdao China Main Port

Picture Example:

Lead Time:

| Quantity(Sets) | 1-1 | >1 |

| Est. Time(days) | 15 | To be negotiated |

Product Description

Automatic Laminated Glass Cutting Machine

1. Brief Introduction:

This set of equipment is the latest development, which equipped with two cutters (upper & bottom sides), SY-3826 is designed to cut thick float glass and laminated glass. It has advantages of easy operation, stable working and high precision.

If the glass size is bigger than 2m*3m, I recommend that you can buy the automatic loading table.

We also have a 2.6m*2m type(Max glass size) laminated glass cutting machine.

Take Eworld, Take the world. (Specializing in the glass machine from the 2002 year)

2. Function:

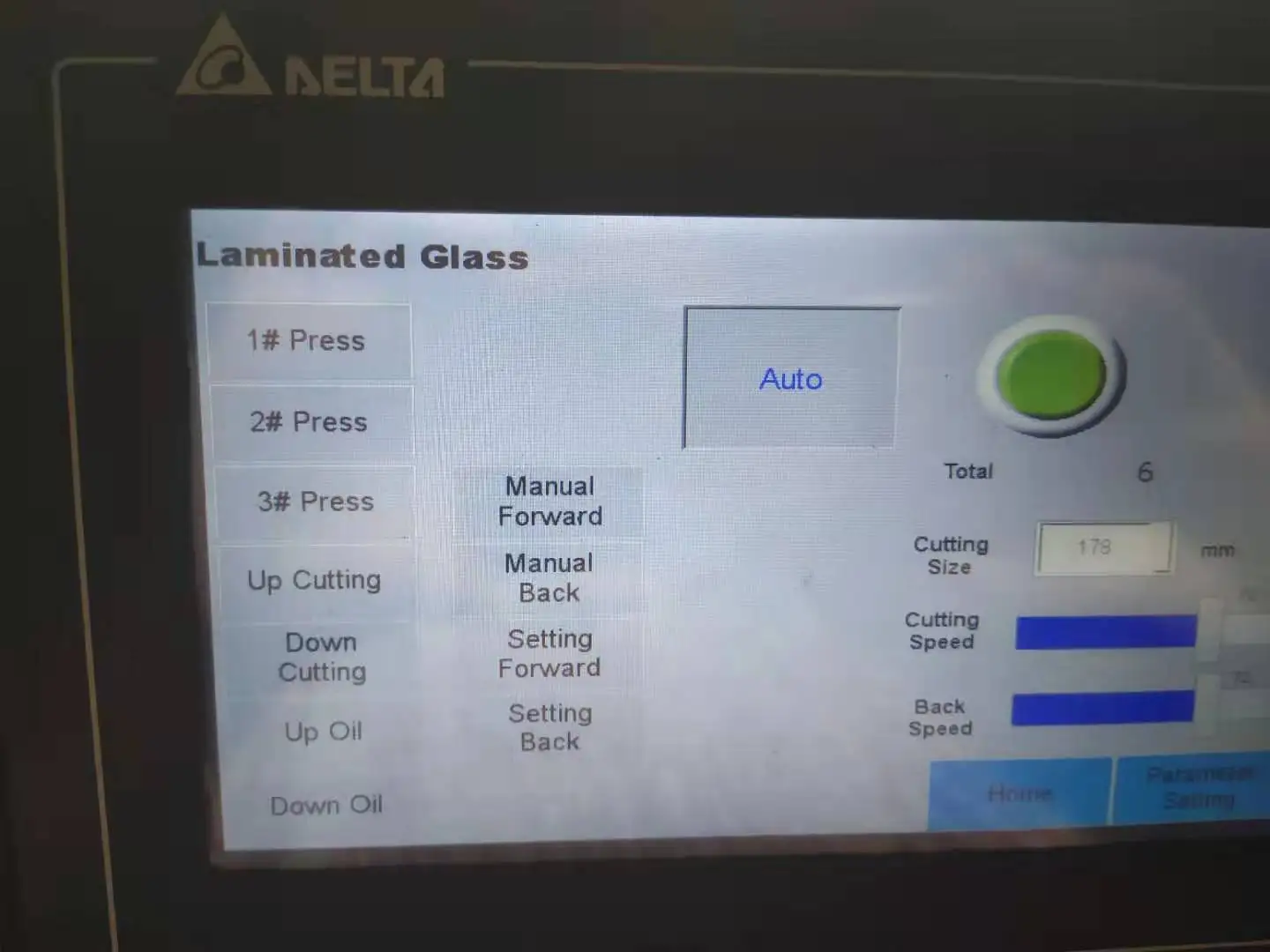

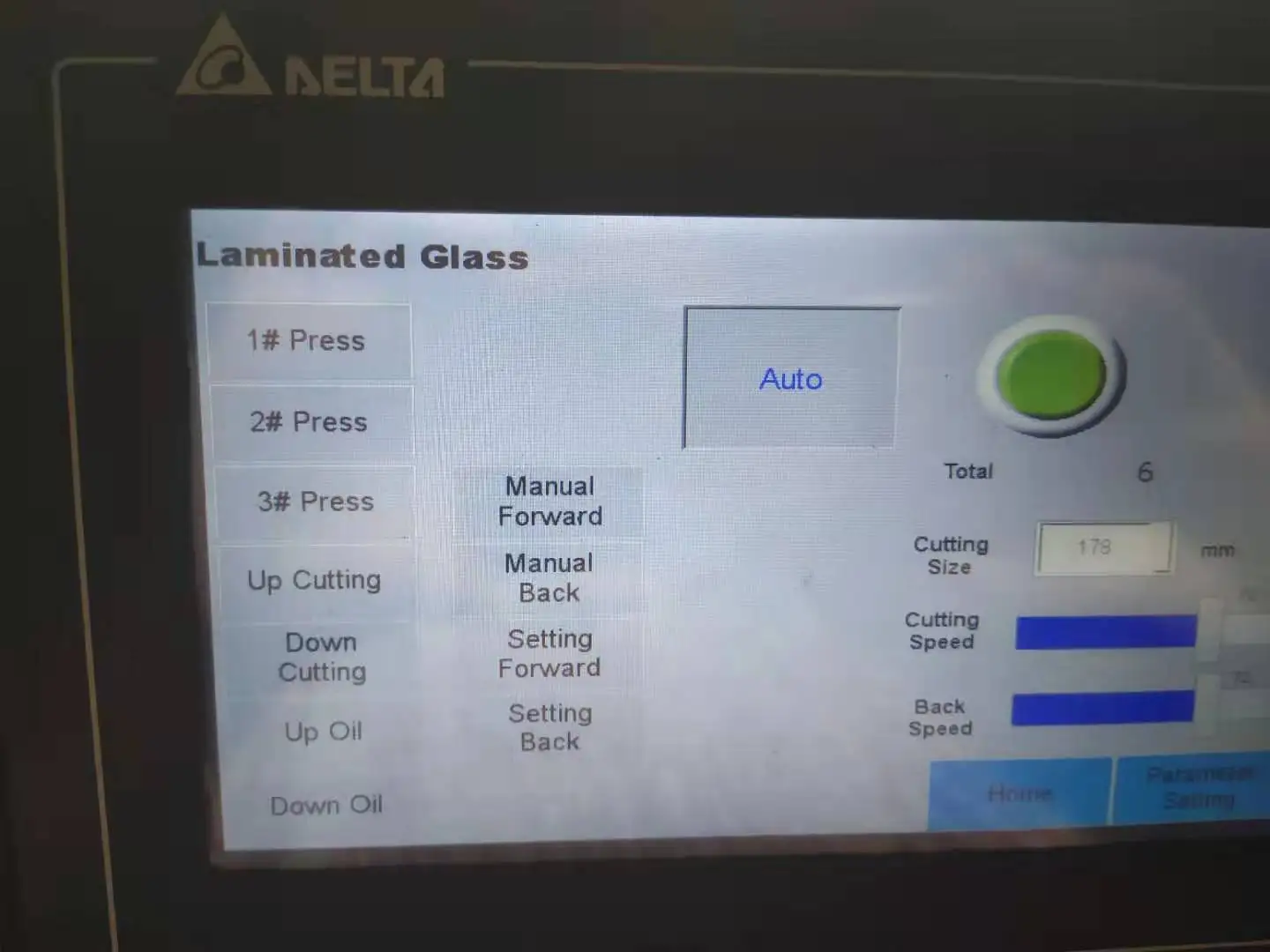

Machine body adopts welded tube which makes the whole machine very stable. Application of synchronous belt conveys system, PLC control system, imported electrical spare parts, stepping motor and LCD makes it much convenient and stable. The Upper & bottom cutter can work at the same time, which ensures high conformity and easy breaking after cutting.

3. Technical Parameters:

| Max. glass cutting size | 3660×2440(mm) |

| Min. glass cutting size | 100×100(mm) |

| Cutting glass thickness | 3+0.38+3----10+0.76+10mm ( laminated glass ) |

| Cutting efficiency | 3-4 minutes/big piece |

| Cutting Error ( parallel ) | ≤±0.5mm |

| Diagonal Error | ≤±1mm/m |

| Cutter life | 30000-50000 meters |

| Workers | 1-2 person |

4. Operation:

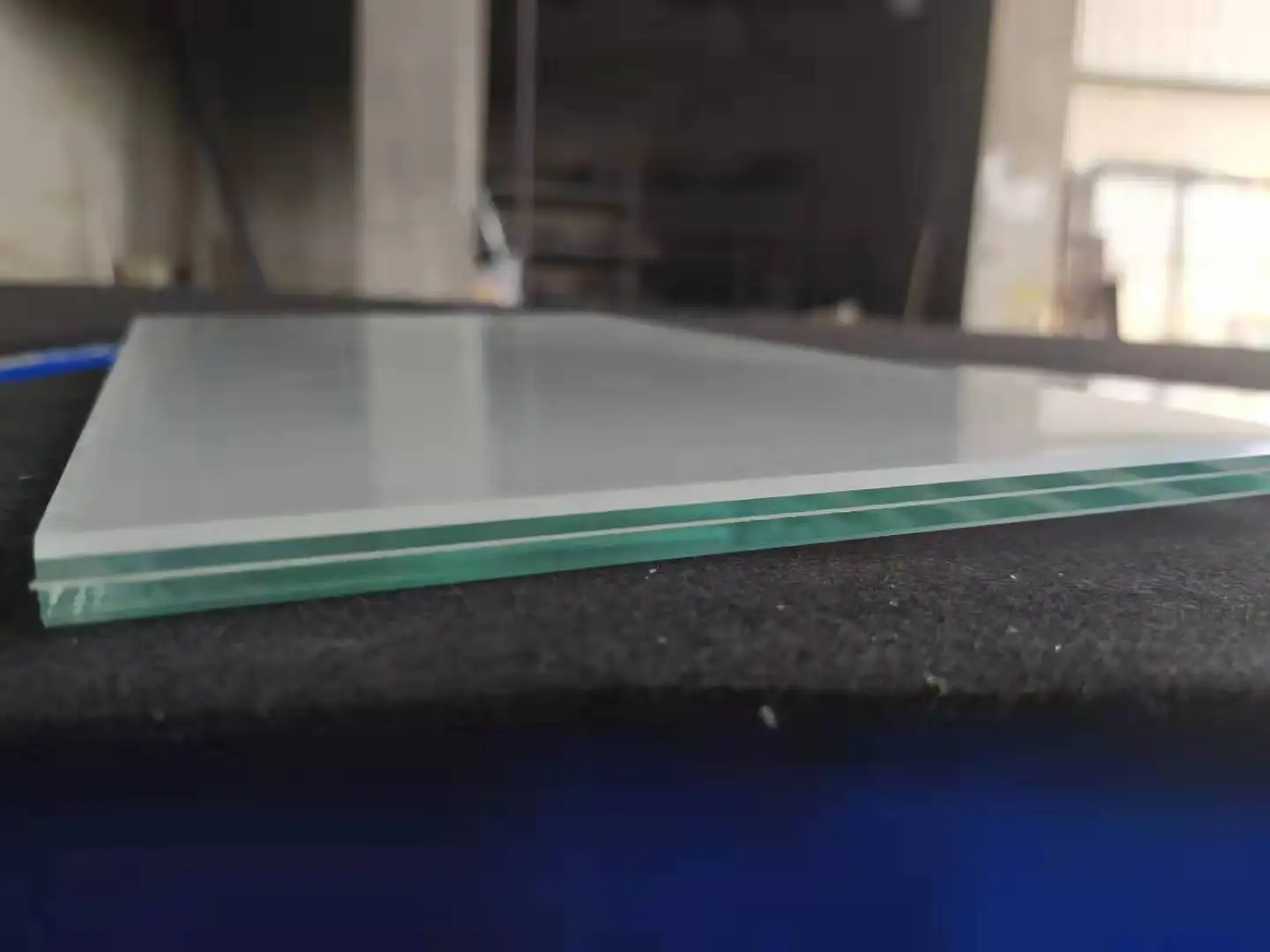

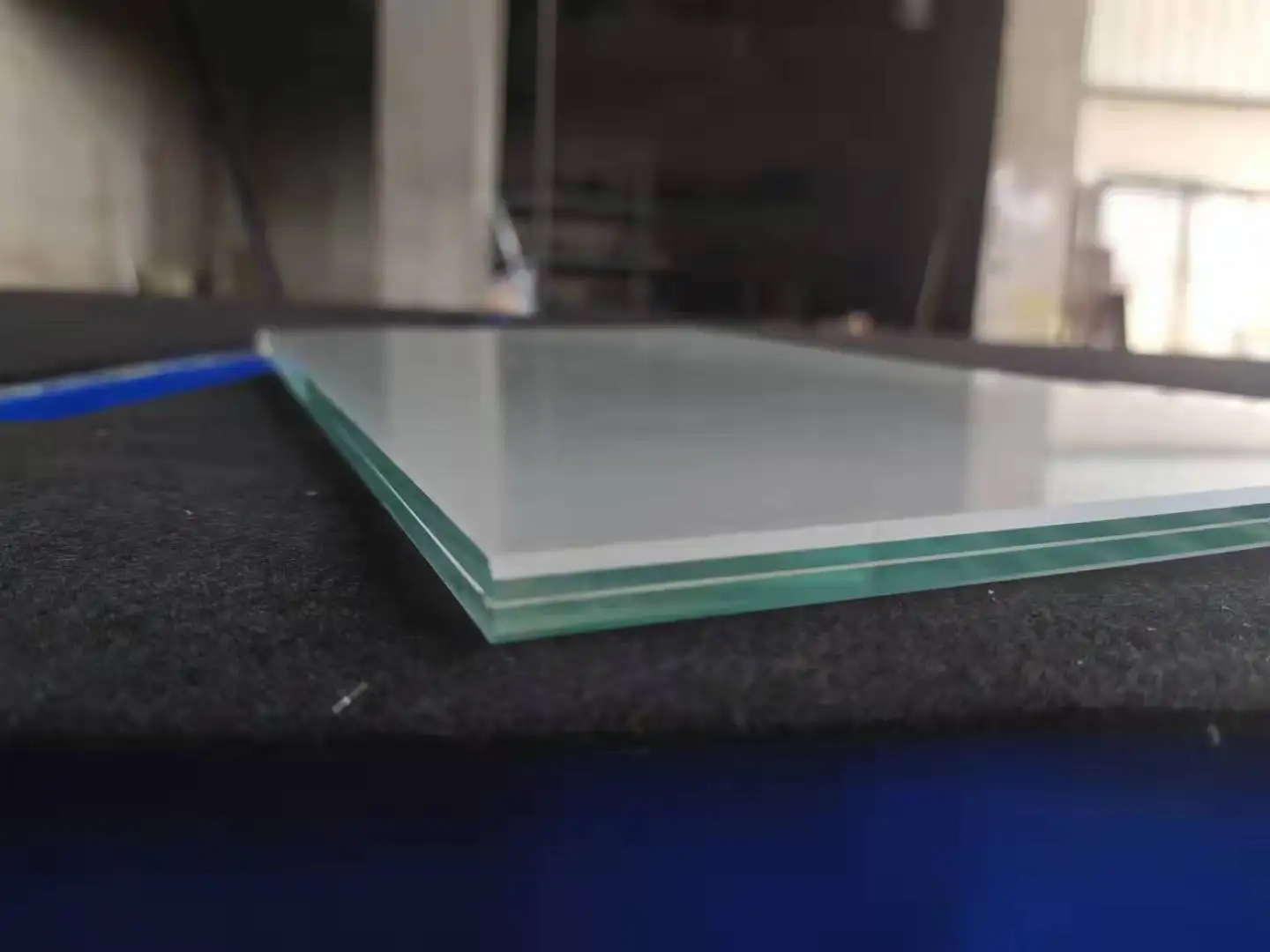

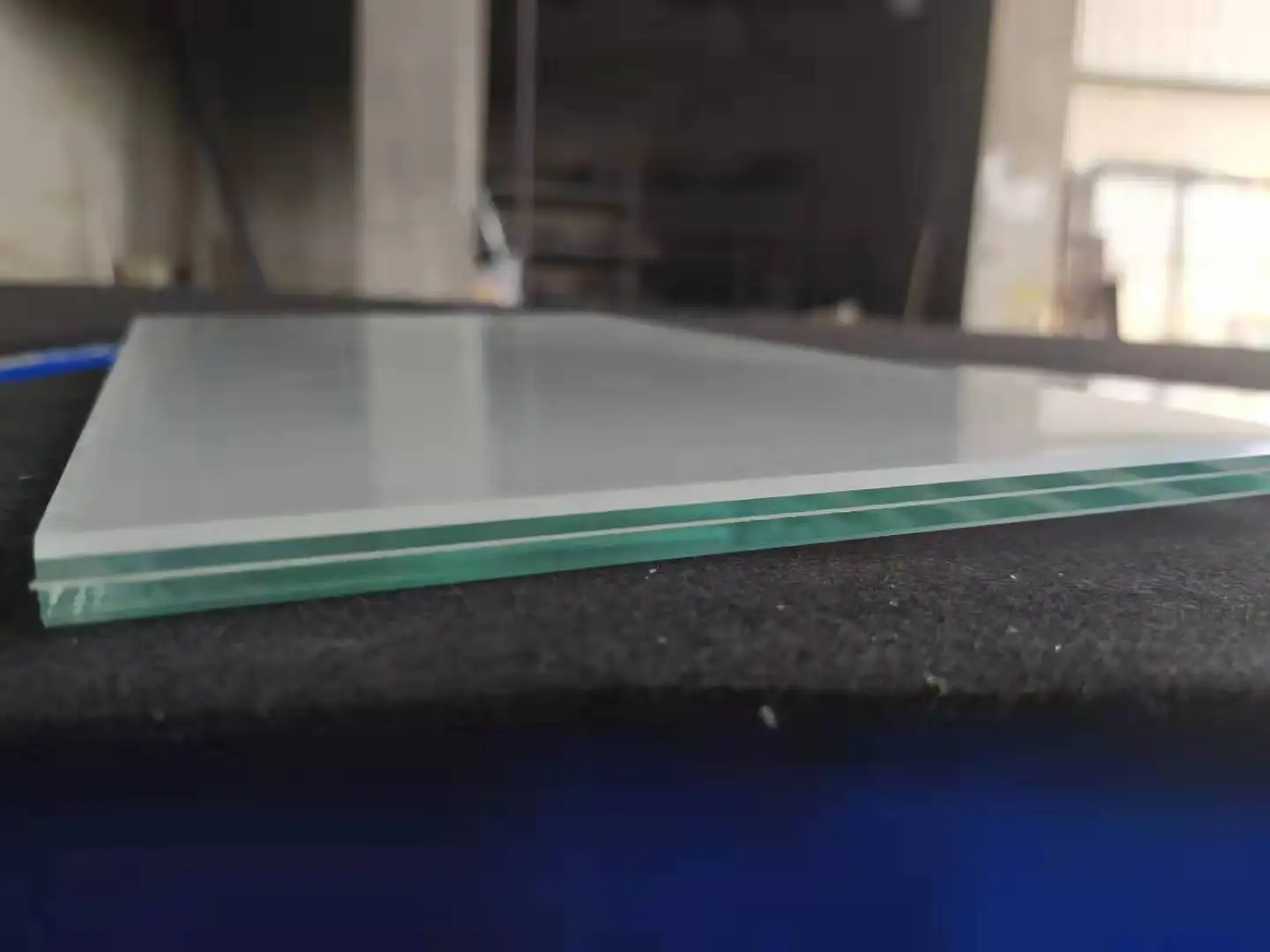

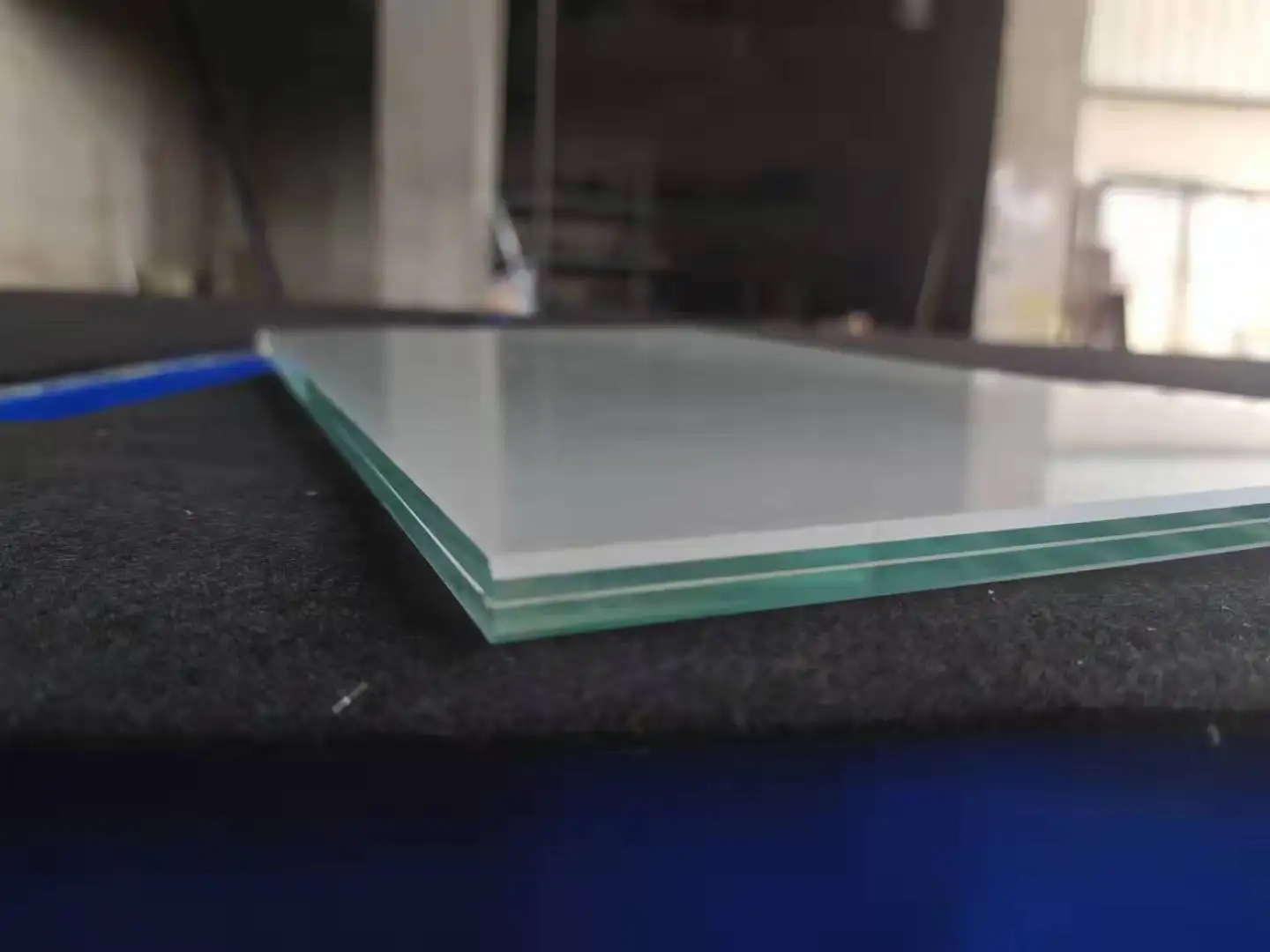

5. Samples:

10mm+0.76mm+10mm

In general, the laminated glass only needs cut once then the glass will separate. We test the 10mm+0.76 Eva film +10 mm and we can get the separated laminated glass does not need the heater.

*20years factory production experience*3 years machine warranty

*156 exported country experience

*20000 square meters Glass machine&upvc windows machine factory

*Shandong Eworld Machine Co., Ltd.

Shandong Eworld Machine Co., Ltd. is one of the famous and big manufacturers of glass equipment, windows equipment, CNC equipment.

Since its inception in 2002, and after many years of development and growth, the company is now playing a leading role in glass machinery and windows door machine inChina Eworld group has 2 factories, which are located in Jinan City. Advanced products, exquisite techniques, solid working, and cordial services

About glass deep processing machines, we are professional and have full set certificates.For every glass cutting machine, we have

serious quality control for every machine and every parts before it leaves our factory.

We went to many exhibitions in China to expand our reputation.

Welcome to visit our factory!If you have plan to come to China and see our machines, please contact us at least 15 days in advance

then we can arrange our

schedule and arrange to treat you.

No matter which transport method you choose, we will pick up you.

If you have any questions, please feel free to contact us.

24*7, we always be here !

FAQ

Question:Are you manufacture?

Answer:Yes,we are the professional manufacture which have more than 5 workshops.

Question: How about the service ?

Answer:

1).reply it at once if from Ali-trademanager,if by email,it reply it within 12 hour

2).deliver max. days within 15 days

3).24 hours for after -sale serive

4).more than 12 years experience in this kind machine field

5).fluent english ,communication barrier free

Question:What’s the guarantee ?

Answer:

1).Our guarantee for 18 months.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).2 year quality guaranty for the machine (excluding the consumables)

5).We will provide the consumable parts at an agency price

6).24 hours on line service each day, free technical support.

Q: Do you provide equipment operation training?

Answer:Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. Allof our engineers have passport.

Question:if our price is higher than another company or factories ?

Answer:please check, what is is the different of the machine parts ,service and guarantee,especially the machine inner electric parts,sometimes, if machines have breakdown, the most reason is the machine inner electric parts problem, but we use the famous andreliable parts for the machines inside.

Question:How long is the delivery time ?

Answer:For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients specific requirements, it would be 15 to 30 days.

Question: What is the payment ?

Answer:Any payment method you want,such as L/C,T/T,D/P,West-union and so on.

Overview

Quick Details

Applicable Industries: Manufacturing Plant

After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location: None

Showroom Location: None

Condition: New

Machine Type: Glass Cutting Machine

Production Capacity: 10sets/month

Place of Origin: Shandong, China

Brand Name: Eworld Machine

Voltage: As request

Power: 21kw

Dimension(L*W*H): 4500*3800*900mm

Certification: ce

Warranty: More than 5 years

After-sales Service Provided: Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

Key Selling Points: Easy to Operate

Glass Thickness: 1-40mm

Machinery Test Report: Provided

Video outgoing inspection: Provided

Marketing Type: New Product 2020

Warranty of core components: 1 Year

Core Components: Pressure vessel, Motor, Bearing, Gear, PLC, Pump, Engine, Gearbox

Name: Glass Cutting Table

Usage: Cut laminated and thick glass

Function: Multifunction

Color: Customers' Request

Seaport: Qingdao Port

Material: Stainless Steel

Model: Eworld

Service: Full set after-sale services

Glass thickness: 3-25mm

Style: High automatic

Supply Ability

Supply Ability: 10 Set/Sets per Month

Packaging & Delivery

Packaging Details: Wooden case Seaworthy package

Port: Qingdao China Main Port

Picture Example:

Lead Time:

| Quantity(Sets) | 1-1 | >1 |

| Est. Time(days) | 15 | To be negotiated |

Product Description

Automatic Laminated Glass Cutting Machine

1. Brief Introduction:

This set of equipment is the latest development, which equipped with two cutters (upper & bottom sides), SY-3826 is designed to cut thick float glass and laminated glass. It has advantages of easy operation, stable working and high precision.

If the glass size is bigger than 2m*3m, I recommend that you can buy the automatic loading table.

We also have a 2.6m*2m type(Max glass size) laminated glass cutting machine.

Take Eworld, Take the world. (Specializing in the glass machine from the 2002 year)

2. Function:

Machine body adopts welded tube which makes the whole machine very stable. Application of synchronous belt conveys system, PLC control system, imported electrical spare parts, stepping motor and LCD makes it much convenient and stable. The Upper & bottom cutter can work at the same time, which ensures high conformity and easy breaking after cutting.

3. Technical Parameters:

| Max. glass cutting size | 3660×2440(mm) |

| Min. glass cutting size | 100×100(mm) |

| Cutting glass thickness | 3+0.38+3----10+0.76+10mm ( laminated glass ) |

| Cutting efficiency | 3-4 minutes/big piece |

| Cutting Error ( parallel ) | ≤±0.5mm |

| Diagonal Error | ≤±1mm/m |

| Cutter life | 30000-50000 meters |

| Workers | 1-2 person |

4. Operation:

5. Samples:

10mm+0.76mm+10mm

In general, the laminated glass only needs cut once then the glass will separate. We test the 10mm+0.76 Eva film +10 mm and we can get the separated laminated glass does not need the heater.

*20years factory production experience*3 years machine warranty

*156 exported country experience

*20000 square meters Glass machine&upvc windows machine factory

*Shandong Eworld Machine Co., Ltd.

Shandong Eworld Machine Co., Ltd. is one of the famous and big manufacturers of glass equipment, windows equipment, CNC equipment.

Since its inception in 2002, and after many years of development and growth, the company is now playing a leading role in glass machinery and windows door machine inChina Eworld group has 2 factories, which are located in Jinan City. Advanced products, exquisite techniques, solid working, and cordial services

About glass deep processing machines, we are professional and have full set certificates.For every glass cutting machine, we have

serious quality control for every machine and every parts before it leaves our factory.

We went to many exhibitions in China to expand our reputation.

Welcome to visit our factory!If you have plan to come to China and see our machines, please contact us at least 15 days in advance

then we can arrange our

schedule and arrange to treat you.

No matter which transport method you choose, we will pick up you.

If you have any questions, please feel free to contact us.

24*7, we always be here !

FAQ

Question:Are you manufacture?

Answer:Yes,we are the professional manufacture which have more than 5 workshops.

Question: How about the service ?

Answer:

1).reply it at once if from Ali-trademanager,if by email,it reply it within 12 hour

2).deliver max. days within 15 days

3).24 hours for after -sale serive

4).more than 12 years experience in this kind machine field

5).fluent english ,communication barrier free

Question:What’s the guarantee ?

Answer:

1).Our guarantee for 18 months.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).2 year quality guaranty for the machine (excluding the consumables)

5).We will provide the consumable parts at an agency price

6).24 hours on line service each day, free technical support.

Q: Do you provide equipment operation training?

Answer:Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. Allof our engineers have passport.

Question:if our price is higher than another company or factories ?

Answer:please check, what is is the different of the machine parts ,service and guarantee,especially the machine inner electric parts,sometimes, if machines have breakdown, the most reason is the machine inner electric parts problem, but we use the famous andreliable parts for the machines inside.

Question:How long is the delivery time ?

Answer:For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients specific requirements, it would be 15 to 30 days.

Question: What is the payment ?

Answer:Any payment method you want,such as L/C,T/T,D/P,West-union and so on.

Eworld Machine produces high-quality machines, also pays attention to the package. The machines will be packed with steel pallets and standard export wooden cases, to make sure customers will receive the machines they ordered Intact.

Eworld Machine produces high-quality machines, also pays attention to the package. The machines will be packed with steel pallets and standard export wooden cases, to make sure customers will receive the machines they ordered Intact.

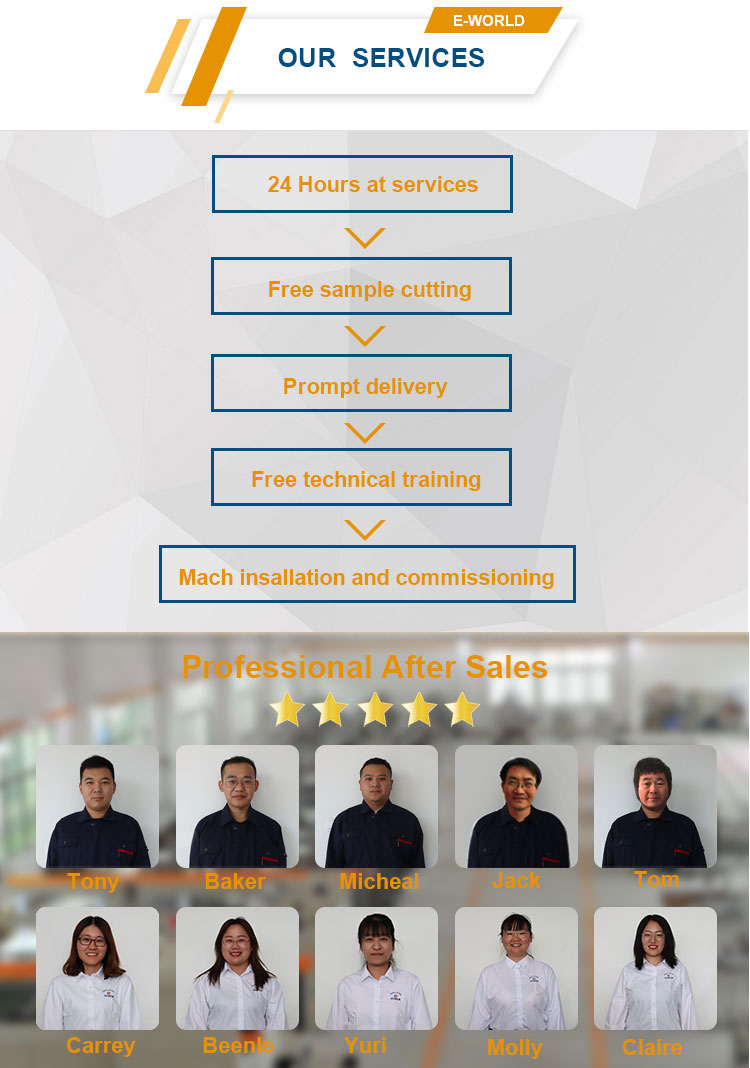

1. Our Goal

Eword strives to find a balance between quality and price so that customers can buy the best machine and we can win-win. Eworld Machine provides full set services and high-quality but low-price products. We are always looking for long-term cooperation, not one-time deal.

2. Pre-sale

Eworld provides 24 hours high-quality service. When clients contact Eworld and ask for products, E-World answers at once, except our clerk's sleep, which condition we answer within 10hours. Eworld understands how important it is for the customers to choose a suitable machine, we are ready to come up with the best solution for customers.

3. On-sale

For all your requests, we will supply the best solution to you as soon as possible. If you have any inquiries or problems, please contact us by E-mail, skype, Alibaba, WhatsApp, phone, etc.

Eworld welcome customers to visit the factory, we will pick you up from the airport or train station. Eworld location is convenient to welcome clients because of next to the train station.

4. After-sale service

When customers buy the glass processing machine, E-World promises that the machine will be delivered in 20-25 days after deposit.

E-World arranges commodity packages suitable for the shipment of sea. E-World provides English instruction about manual guide and video technical support. Any problems please let us know, and we will give detailed supports and advice.

E-World promises worry-free repair of one whole year after installation, the original fault parts damaged, be free of any charges. When a serious breakdown and big fault happens, E-World has engineered and they can fly there to solve it.

1. Our Goal

Eword strives to find a balance between quality and price so that customers can buy the best machine and we can win-win. Eworld Machine provides full set services and high-quality but low-price products. We are always looking for long-term cooperation, not one-time deal.

2. Pre-sale

Eworld provides 24 hours high-quality service. When clients contact Eworld and ask for products, E-World answers at once, except our clerk's sleep, which condition we answer within 10hours. Eworld understands how important it is for the customers to choose a suitable machine, we are ready to come up with the best solution for customers.

3. On-sale

For all your requests, we will supply the best solution to you as soon as possible. If you have any inquiries or problems, please contact us by E-mail, skype, Alibaba, WhatsApp, phone, etc.

Eworld welcome customers to visit the factory, we will pick you up from the airport or train station. Eworld location is convenient to welcome clients because of next to the train station.

4. After-sale service

When customers buy the glass processing machine, E-World promises that the machine will be delivered in 20-25 days after deposit.

E-World arranges commodity packages suitable for the shipment of sea. E-World provides English instruction about manual guide and video technical support. Any problems please let us know, and we will give detailed supports and advice.

E-World promises worry-free repair of one whole year after installation, the original fault parts damaged, be free of any charges. When a serious breakdown and big fault happens, E-World has engineered and they can fly there to solve it.

Shandong Eworld Machine Co., Ltd is one of the most famous and big manufacturers of glass and CNC equipment since its inception in 2001. I am sure that you will be satisfied with our products quality and competitive price. E-World is confident to maintain our business relationship as we are one of the biggest glass equipment manufacturers, which capable of providing quality goods, competitive price and fast delivery, quick response at the same time.

Shandong Eworld Machine Co., Ltd is one of the most famous and big manufacturers of glass and CNC equipment since its inception in 2001. I am sure that you will be satisfied with our products quality and competitive price. E-World is confident to maintain our business relationship as we are one of the biggest glass equipment manufacturers, which capable of providing quality goods, competitive price and fast delivery, quick response at the same time.

1. Question: Are you manufacture?

Answer:

Yes, we are professional manufacture which has more than 5 workshops.

2. Question: How about the service?

Answer:

1). reply it at once if from Ali-trade manager, if by email, it replies it within 12 hour

2). deliver max. days within 15 days

3). 24 hours for after-sale service

4). more than 12 years experience in this kind of machine field

5). fluent English, communication barrier-free

3. Question: What’s the guarantee?

Answer:

1). Our guarantee for 18 months.

2). 24 hour’s technical support by email or calling

3). English manual and video tutorial

4). 2-year quality guaranty for the machine (excluding the consumables)

5). We will provide the consumable parts at an agency price

6). 24 hours online service each day, free technical support.

4. Question: Do you provide equipment operation training?

Answer:

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

5. Question: if our price is higher than another company or factories?

Answer:

please check, what is the difference of the machine parts, service and guarantee, especially the machine inner electric parts, sometimes, if machines have a breakdown, the most reason is the machine inner electric parts problem, but we use the famous and reliable parts for the machines inside.

6. Question: How long is the delivery time?

Answer:

For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients' specific requirements, it would be 15 to 30 days.

7. Question: What is the payment?

Answer:

Any payment method you want, such as L/C, T/T, D/P, West-union and so on.

1. Question: Are you manufacture?

Answer:

Yes, we are professional manufacture which has more than 5 workshops.

2. Question: How about the service?

Answer:

1). reply it at once if from Ali-trade manager, if by email, it replies it within 12 hour

2). deliver max. days within 15 days

3). 24 hours for after-sale service

4). more than 12 years experience in this kind of machine field

5). fluent English, communication barrier-free

3. Question: What’s the guarantee?

Answer:

1). Our guarantee for 18 months.

2). 24 hour’s technical support by email or calling

3). English manual and video tutorial

4). 2-year quality guaranty for the machine (excluding the consumables)

5). We will provide the consumable parts at an agency price

6). 24 hours online service each day, free technical support.

4. Question: Do you provide equipment operation training?

Answer:

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

5. Question: if our price is higher than another company or factories?

Answer:

please check, what is the difference of the machine parts, service and guarantee, especially the machine inner electric parts, sometimes, if machines have a breakdown, the most reason is the machine inner electric parts problem, but we use the famous and reliable parts for the machines inside.

6. Question: How long is the delivery time?

Answer:

For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients' specific requirements, it would be 15 to 30 days.

7. Question: What is the payment?

Answer:

Any payment method you want, such as L/C, T/T, D/P, West-union and so on.