WhatsApp: +8615665767071 Email: info@eworldmachine.com

English

EnglishHLB1600

Eworld

| Availability: | |

|---|---|

| Quantity: | |

Model NO.: | Rubber Strip Horizontal Automatic Insulating Glass Machine |

Price | |

Certification: | CE |

Type: | |

Export Markets: | North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Western Europe |

Additional Info.

Trademark: | EWORLD |

Packing: | Packed in Wooden Case, Seaworthy Package |

HS Code: | 8464201000 |

Production Capacity: | 10 Sets/ Month |

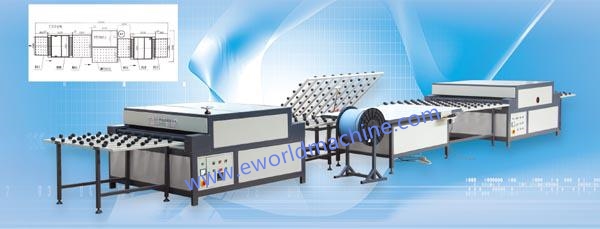

BX1600 Rubber Strip Horizontal Automatic Insulating Glass Machine

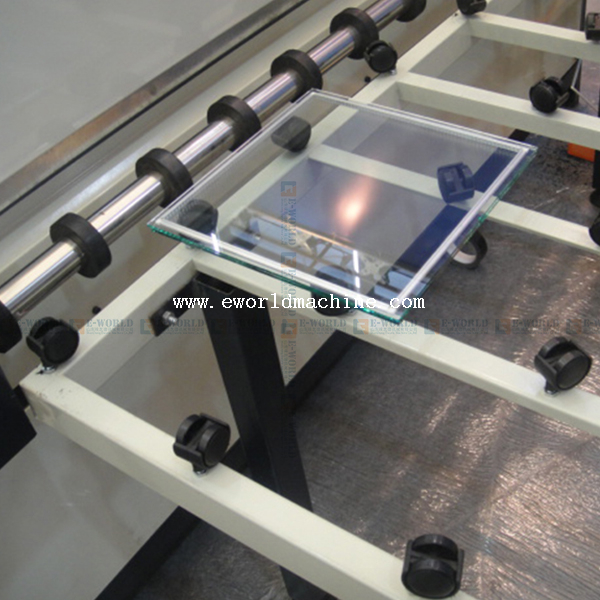

1.BX1600 glass washing and dry machine

1).Main Funtion Intrduction:

1. glass washing machine is a special multifunctional equipment for flat glass cleaning.have good dry effect of cleaning.

2. dry section adopt sponge stick to absorb water

3. washing section and water systerm adopt stainless steel and corrosion-resistant materials

4. recirculating rinse to save water

2).Main Technical Date:

1. total power:8.43KW

2. voltage:

3. working speed:1.2-5m/min

4. min glass dimension:400mm*400mm

5. max glass dimension:1600mm*2500mm

6. max insulating glass thickness:12mm

7. dimension:4000mm*2000mm*1200mm

Note:the machine has following dimension:

BX1200,BX1500,BX1600,BX1800,BX2500

2.BX1600 hot roller press machine

1).Main Funtion Intrduction:

• Adopt halogen heating pipe , high heating efficiency, longer life.

• Adopting the stepless speed regulation mechanism can relize stepless speed regulation and smoothly drive.

• Adopting precision measurement systems can make the upper-lower rubber roller get the exact size needed.

• The incubator produced by the resistant high temperature material is to prevent heat loss.

• Four pairs of two different hardness rubber rollers can ensure to make the whole glass uniform pressure, and make the size of thickness accurate.

•The main components imported ensure stable operation of the equipment, reliable performance..

•The digital display temperature control equipment operate more handy.

• The shelf body is made of the high-quality carbon steel material, which is strong light ,the surface sprayed is anti-rust.

2).Main Technical Date:

Input power: 220V

Frequency: 60HZ

Main axis power: 0.37 KW

Heating stove power: 30KW

Processing glass width: 1600mm

Working glass thickness: < 40mm

Glass conveying speed:0 –6m/min

Dimension: 3800*1800*1200mm

Total weight: about 1000KG

Note:the machine has following dimension:

BX1200, BX1600, BX1800

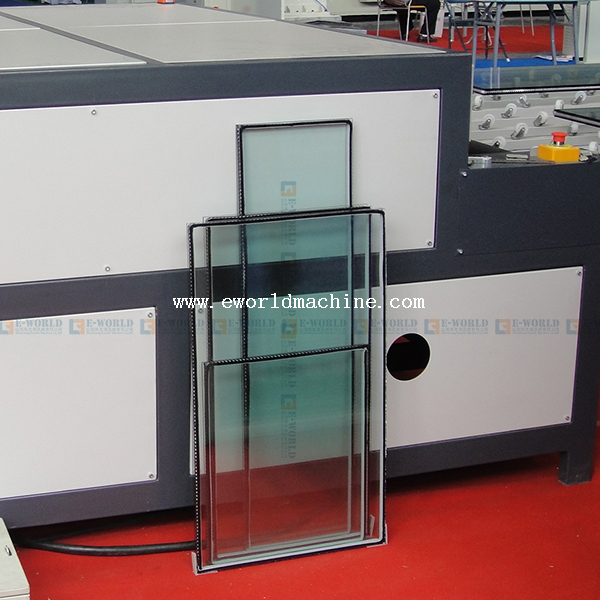

3.Glass assemble table

1).Main Funtion Intrduction:

1.This machine is special designed for installing rubber bar and assembling for saw glass of insulating glass.

2.the machine adopts PLC, accomplish the action circulation of all index units to make glass complete 90-degree angle distributed gynation,locate and lay rubber bar automatically.the table locates through two sides tomake assembly easily.

3.the machine has special-designed hanging-thick table to make glass move smoothly it’s the ideal equipment for producing complex rubber bar insulating glass.

2).Main Technical Date:

Dimendion: 1650*1650*650mm

Power supply: 220V

Max angel: 80 degree

Air pressure: 6KG

Weight 300KG

4. Tilt talbe

it is designed for delivery the finished insulating glass easily

Technical date:

power supply:220v 60hz 3-phase 4-wire

tilt degree:0-80degree

hight:750mm

table size:1200mm*2000mm(as your request)

weight:310KG

*20years factory production experience*3 years machine warranty

*156 exported country experience

*20000 square meters Glass machine&upvc windows machine factory

*Shandong Eworld Machine Co., Ltd.

Shandong Eworld Machine Co., Ltd. is one of the famous and big manufacturers of glass equipment, windows equipment, CNC equipment.

Since its inception in 2002, and after many years of development and growth, the company is now playing a leading role in glass machinery and windows door machine inChina Eworld group has 2 factories, which are located in Jinan City. Advanced products, exquisite techniques, solid working, and cordial services

About glass deep processing machines, we are professional and have full set certificates.For every glass cutting machine, we have

serious quality control for every machine and every parts before it leaves our factory.

We went to many exhibitions in China to expand our reputation.

We went to many exhibitions in China to expand our reputation.

Welcome to visit our factory!If you have plan to come to China and see our machines, please contact us at least 15 days in advance

Welcome to visit our factory!If you have plan to come to China and see our machines, please contact us at least 15 days in advance

then we can arrange our

schedule and arrange to treat you.

No matter which transport method you choose, we will pick up you.

If you have any questions, please feel free to contact us.

24*7, we always be here !

FAQ

Question:Are you manufacture?

Answer:Yes,we are the professional manufacture which have more than 5 workshops.

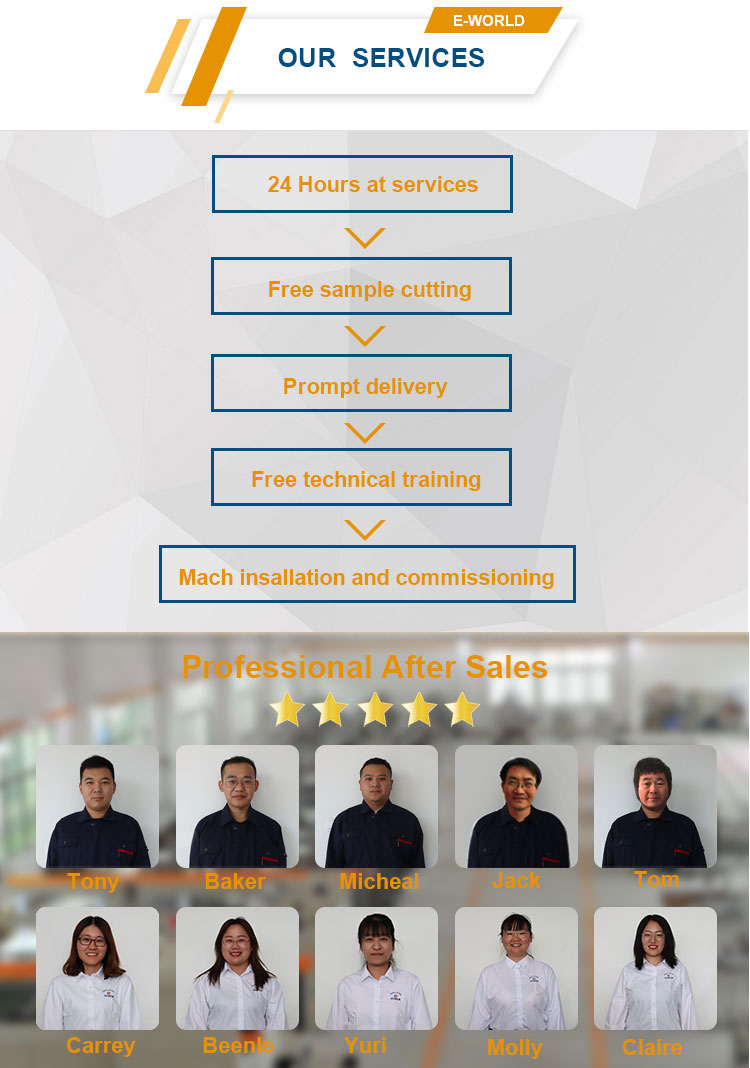

Question: How about the service ?

Answer:

1).reply it at once if from Ali-trademanager,if by email,it reply it within 12 hour

2).deliver max. days within 15 days

3).24 hours for after -sale serive

4).more than 12 years experience in this kind machine field

5).fluent english ,communication barrier free

Question:What’s the guarantee ?

Answer:

1).Our guarantee for 18 months.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).2 year quality guaranty for the machine (excluding the consumables)

5).We will provide the consumable parts at an agency price

6).24 hours on line service each day, free technical support.

Q: Do you provide equipment operation training?

Answer:Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. Allof our engineers have passport.

Question:if our price is higher than another company or factories ?

Answer:please check, what is is the different of the machine parts ,service and guarantee,especially the machine inner electric parts,sometimes, if machines have breakdown, the most reason is the machine inner electric parts problem, but we use the famous andreliable parts for the machines inside.

Question:How long is the delivery time ?

Answer:For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients specific requirements, it would be 15 to 30 days.

Question: What is the payment ?

Answer:Any payment method you want,such as L/C,T/T,D/P,West-union and so on.

Model NO.: | Rubber Strip Horizontal Automatic Insulating Glass Machine |

Price | |

Certification: | CE |

Type: | |

Export Markets: | North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Western Europe |

Additional Info.

Trademark: | EWORLD |

Packing: | Packed in Wooden Case, Seaworthy Package |

HS Code: | 8464201000 |

Production Capacity: | 10 Sets/ Month |

BX1600 Rubber Strip Horizontal Automatic Insulating Glass Machine

1.BX1600 glass washing and dry machine

1).Main Funtion Intrduction:

1. glass washing machine is a special multifunctional equipment for flat glass cleaning.have good dry effect of cleaning.

2. dry section adopt sponge stick to absorb water

3. washing section and water systerm adopt stainless steel and corrosion-resistant materials

4. recirculating rinse to save water

2).Main Technical Date:

1. total power:8.43KW

2. voltage:

3. working speed:1.2-5m/min

4. min glass dimension:400mm*400mm

5. max glass dimension:1600mm*2500mm

6. max insulating glass thickness:12mm

7. dimension:4000mm*2000mm*1200mm

Note:the machine has following dimension:

BX1200,BX1500,BX1600,BX1800,BX2500

2.BX1600 hot roller press machine

1).Main Funtion Intrduction:

• Adopt halogen heating pipe , high heating efficiency, longer life.

• Adopting the stepless speed regulation mechanism can relize stepless speed regulation and smoothly drive.

• Adopting precision measurement systems can make the upper-lower rubber roller get the exact size needed.

• The incubator produced by the resistant high temperature material is to prevent heat loss.

• Four pairs of two different hardness rubber rollers can ensure to make the whole glass uniform pressure, and make the size of thickness accurate.

•The main components imported ensure stable operation of the equipment, reliable performance..

•The digital display temperature control equipment operate more handy.

• The shelf body is made of the high-quality carbon steel material, which is strong light ,the surface sprayed is anti-rust.

2).Main Technical Date:

Input power: 220V

Frequency: 60HZ

Main axis power: 0.37 KW

Heating stove power: 30KW

Processing glass width: 1600mm

Working glass thickness: < 40mm

Glass conveying speed:0 –6m/min

Dimension: 3800*1800*1200mm

Total weight: about 1000KG

Note:the machine has following dimension:

BX1200, BX1600, BX1800

3.Glass assemble table

1).Main Funtion Intrduction:

1.This machine is special designed for installing rubber bar and assembling for saw glass of insulating glass.

2.the machine adopts PLC, accomplish the action circulation of all index units to make glass complete 90-degree angle distributed gynation,locate and lay rubber bar automatically.the table locates through two sides tomake assembly easily.

3.the machine has special-designed hanging-thick table to make glass move smoothly it’s the ideal equipment for producing complex rubber bar insulating glass.

2).Main Technical Date:

Dimendion: 1650*1650*650mm

Power supply: 220V

Max angel: 80 degree

Air pressure: 6KG

Weight 300KG

4. Tilt talbe

it is designed for delivery the finished insulating glass easily

Technical date:

power supply:220v 60hz 3-phase 4-wire

tilt degree:0-80degree

hight:750mm

table size:1200mm*2000mm(as your request)

weight:310KG

*20years factory production experience*3 years machine warranty

*156 exported country experience

*20000 square meters Glass machine&upvc windows machine factory

*Shandong Eworld Machine Co., Ltd.

Shandong Eworld Machine Co., Ltd. is one of the famous and big manufacturers of glass equipment, windows equipment, CNC equipment.

Since its inception in 2002, and after many years of development and growth, the company is now playing a leading role in glass machinery and windows door machine inChina Eworld group has 2 factories, which are located in Jinan City. Advanced products, exquisite techniques, solid working, and cordial services

About glass deep processing machines, we are professional and have full set certificates.For every glass cutting machine, we have

serious quality control for every machine and every parts before it leaves our factory.

We went to many exhibitions in China to expand our reputation.

We went to many exhibitions in China to expand our reputation.

Welcome to visit our factory!If you have plan to come to China and see our machines, please contact us at least 15 days in advance

Welcome to visit our factory!If you have plan to come to China and see our machines, please contact us at least 15 days in advance

then we can arrange our

schedule and arrange to treat you.

No matter which transport method you choose, we will pick up you.

If you have any questions, please feel free to contact us.

24*7, we always be here !

FAQ

Question:Are you manufacture?

Answer:Yes,we are the professional manufacture which have more than 5 workshops.

Question: How about the service ?

Answer:

1).reply it at once if from Ali-trademanager,if by email,it reply it within 12 hour

2).deliver max. days within 15 days

3).24 hours for after -sale serive

4).more than 12 years experience in this kind machine field

5).fluent english ,communication barrier free

Question:What’s the guarantee ?

Answer:

1).Our guarantee for 18 months.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).2 year quality guaranty for the machine (excluding the consumables)

5).We will provide the consumable parts at an agency price

6).24 hours on line service each day, free technical support.

Q: Do you provide equipment operation training?

Answer:Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. Allof our engineers have passport.

Question:if our price is higher than another company or factories ?

Answer:please check, what is is the different of the machine parts ,service and guarantee,especially the machine inner electric parts,sometimes, if machines have breakdown, the most reason is the machine inner electric parts problem, but we use the famous andreliable parts for the machines inside.

Question:How long is the delivery time ?

Answer:For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients specific requirements, it would be 15 to 30 days.

Question: What is the payment ?

Answer:Any payment method you want,such as L/C,T/T,D/P,West-union and so on.