WhatsApp: +8615665767071 Email: info@eworldmachine.com

English

EnglishLB1600

Eworld

8475291900

| Availability: | |

|---|---|

| Quantity: | |

Overview

Quick Details

Applicable Industries: Manufacturing Plant

After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location: None

Showroom Location: None

Condition: New

Machine Type: Glass insulating machine

Production Capacity: 10sets/month

Place of Origin: Shandong, China

Brand Name: Eworld Machine

Voltage: 380V Or 110V

Power: 10kw

Dimension(L*W*H): 20000mm*2500mm*3600mm

Certification: ce

Warranty: 1 Year

After-sales Service Provided: Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

Key Selling Points: Easy to Operate

Glass Thickness: 3-25mm

Machinery Test Report: Provided

Video outgoing-inspection: Provided

Marketing Type: Ordinary Product

Warranty of core components: 1 Year

Core Components: Pressure vessel, Motor, Bearing, Gear, PLC, Pump, Engine, Gearbox

Name: Insulating Glass production line

Usage: Industry field

Model: LBZ2000

Single piece glass thickness: 3-25mm

Feature: High Reliability

Control system: PLC(Mitsubishi)

Max glass size: 2000mm*2500mm

Insulating Glass Thickness(mm): up to 50mm

Washing speed: 0-8m/min

Air pressure: 1.0Mpa

Supply Ability

Supply Ability: 5 Set/Sets per Month

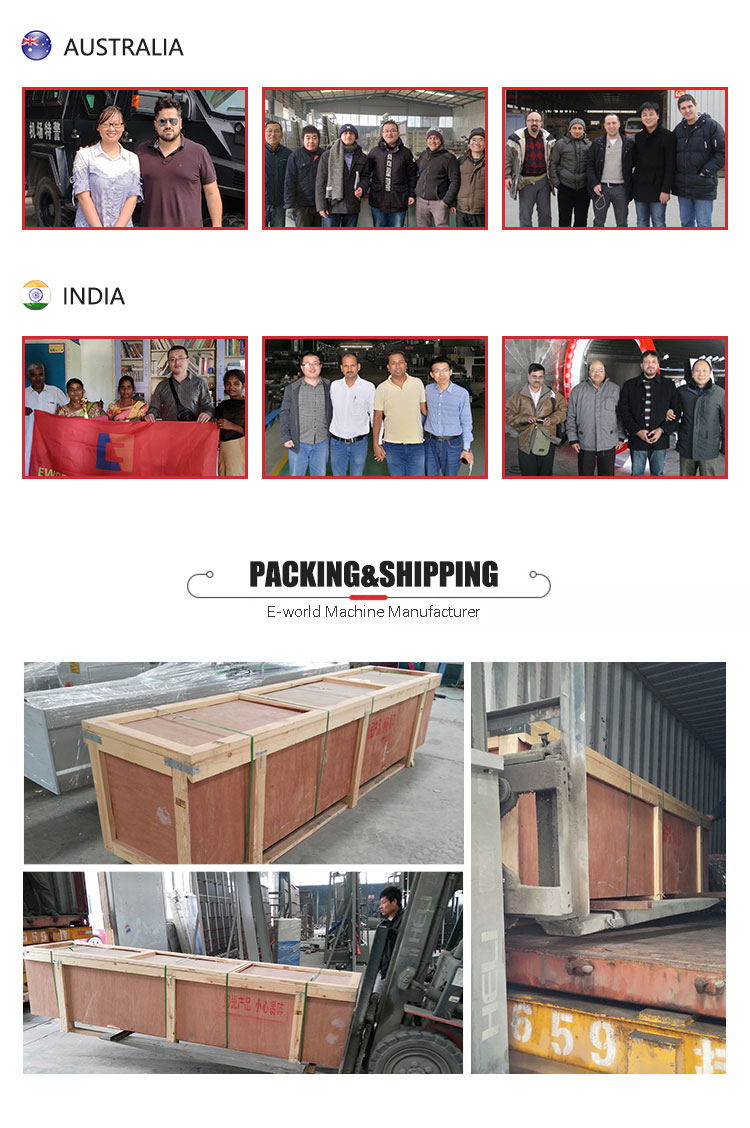

Packaging & Delivery

Packaging Details: wooden case,seaworthy package

Port: Qingdao, china main port

Picture Example:

Lead Time:

| Quantity(Sets) | 1 - 1 | >1 |

| Est. Time(days) | 20 | To be negotiated |

Product Description

Brief introduction

We have an inner combination insulating glass production line(6 sections) and an outer combination insulating glass production line(7 sections). This is 7 sections insulating the glass production line.

The insulating glass production line is the essential machine of insulating glass production line, it can make stepped glass, shaped glass, double layers, and three layers. This Insulating Glass Machine is special equipment for aluminum groove type insulating glass, This can make two-layer and three-layer insulating glasses with equal and unequal glass sheets.

Main Parameter

| Max working size | 2000*2500mm |

| Min working size | 300*500mm |

| Single Glass Thickness | 3-12mm |

| Max IGU thickness | 50mm |

| Washing speed | 0-8m/min |

| Conveyor speed | 45m/min |

| Cycle | 30—40 seconds(900*1200mm) |

| Brusher | 3 pairs |

| Brusher Diameter | Rough: 0.1mm, Fine: 0.06mm |

| Electricity power | 3P 380V/50HZ or 3P 220V/60HZ |

| Dimension | 20000*2500*3600mm |

| Water | 0.5 ton per day |

| Air Exhaust volume | 0.8m3/min |

| Air pressure | 1.0Mpa |

Features

1. Insulating glass line with high automatic level is fully controlled by PLC system, the operation is easy and humanized.

2. Touch screen operation interface. It is easy to transfer between automation and hand-operation.

3. Self-diagnosis system brings much high convenience to the user.

4. Automatically distinguish the film of LOW-E and coated glass.

5. The washing part is completely made of stainless steel, tempered glass door makes the operation inside clearly monitored, Signal switch on the top of the door avoid possible injury to the operator.

6. Energy saving and interrupted system for the washing machine.

7. Unique water nozzle design makes the maintenance easy and fast.

8. Heating system for the water and blowing air. Start it when the ambient temperature no more than 7 degree.

9. Automatic control 6 brushers for Glass.

10. There is a special system for Producing triple insulating glass.

11. Having a system for the wrong operation and automatically wait for the second glass following.

12. Automatic assembly inside the press machine.

13. High-class casting and processing of spare parts assure good stability of the line.

14. The key connections use expanded joint instead of common union. This guarantees high adjustment precision and conveying reliability.

*20years factory production experience*3 years machine warranty

*156 exported country experience

*20000 square meters Glass machine&upvc windows machine factory

*Shandong Eworld Machine Co., Ltd.

Shandong Eworld Machine Co., Ltd. is one of the famous and big manufacturers of glass equipment, windows equipment, CNC equipment.

Since its inception in 2002, and after many years of development and growth, the company is now playing a leading role in glass machinery and windows door machine inChina Eworld group has 2 factories, which are located in Jinan City. Advanced products, exquisite techniques, solid working, and cordial services

We went to many exhibitions in China to expand our reputation.

Welcome to visit our factory!If you have plan to come to China and see our machines, please contact us at least 15 days in advance

then we can arrange our

schedule and arrange to treat you.

No matter which transport method you choose, we will pick up you.

If you have any questions, please feel free to contact us.

24*7, we always be here !

FAQ

Question:Are you manufacture?

Answer:Yes,we are the professional manufacture which have more than 5 workshops.

Question: How about the service ?

Answer:

1).reply it at once if from Ali-trademanager,if by email,it reply it within 12 hour

2).deliver max. days within 15 days

3).24 hours for after -sale serive

4).more than 12 years experience in this kind machine field

5).fluent english ,communication barrier free

Question:What’s the guarantee ?

Answer:

1).Our guarantee for 18 months.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).2 year quality guaranty for the machine (excluding the consumables)

5).We will provide the consumable parts at an agency price

6).24 hours on line service each day, free technical support.

Q: Do you provide equipment operation training?

Answer:Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. Allof our engineers have passport.

Question:if our price is higher than another company or factories ?

Answer:please check, what is is the different of the machine parts ,service and guarantee,especially the machine inner electric parts,sometimes, if machines have breakdown, the most reason is the machine inner electric parts problem, but we use the famous andreliable parts for the machines inside.

Question:How long is the delivery time ?

Answer:For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients specific requirements, it would be 15 to 30 days.

Question: What is the payment ?

Answer:Any payment method you want,such as L/C,T/T,D/P,West-union and so on.

Overview

Quick Details

Applicable Industries: Manufacturing Plant

After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location: None

Showroom Location: None

Condition: New

Machine Type: Glass insulating machine

Production Capacity: 10sets/month

Place of Origin: Shandong, China

Brand Name: Eworld Machine

Voltage: 380V Or 110V

Power: 10kw

Dimension(L*W*H): 20000mm*2500mm*3600mm

Certification: ce

Warranty: 1 Year

After-sales Service Provided: Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

Key Selling Points: Easy to Operate

Glass Thickness: 3-25mm

Machinery Test Report: Provided

Video outgoing-inspection: Provided

Marketing Type: Ordinary Product

Warranty of core components: 1 Year

Core Components: Pressure vessel, Motor, Bearing, Gear, PLC, Pump, Engine, Gearbox

Name: Insulating Glass production line

Usage: Industry field

Model: LBZ2000

Single piece glass thickness: 3-25mm

Feature: High Reliability

Control system: PLC(Mitsubishi)

Max glass size: 2000mm*2500mm

Insulating Glass Thickness(mm): up to 50mm

Washing speed: 0-8m/min

Air pressure: 1.0Mpa

Supply Ability

Supply Ability: 5 Set/Sets per Month

Packaging & Delivery

Packaging Details: wooden case,seaworthy package

Port: Qingdao, china main port

Picture Example:

Lead Time:

| Quantity(Sets) | 1 - 1 | >1 |

| Est. Time(days) | 20 | To be negotiated |

Product Description

Brief introduction

We have an inner combination insulating glass production line(6 sections) and an outer combination insulating glass production line(7 sections). This is 7 sections insulating the glass production line.

The insulating glass production line is the essential machine of insulating glass production line, it can make stepped glass, shaped glass, double layers, and three layers. This Insulating Glass Machine is special equipment for aluminum groove type insulating glass, This can make two-layer and three-layer insulating glasses with equal and unequal glass sheets.

Main Parameter

| Max working size | 2000*2500mm |

| Min working size | 300*500mm |

| Single Glass Thickness | 3-12mm |

| Max IGU thickness | 50mm |

| Washing speed | 0-8m/min |

| Conveyor speed | 45m/min |

| Cycle | 30—40 seconds(900*1200mm) |

| Brusher | 3 pairs |

| Brusher Diameter | Rough: 0.1mm, Fine: 0.06mm |

| Electricity power | 3P 380V/50HZ or 3P 220V/60HZ |

| Dimension | 20000*2500*3600mm |

| Water | 0.5 ton per day |

| Air Exhaust volume | 0.8m3/min |

| Air pressure | 1.0Mpa |

Features

1. Insulating glass line with high automatic level is fully controlled by PLC system, the operation is easy and humanized.

2. Touch screen operation interface. It is easy to transfer between automation and hand-operation.

3. Self-diagnosis system brings much high convenience to the user.

4. Automatically distinguish the film of LOW-E and coated glass.

5. The washing part is completely made of stainless steel, tempered glass door makes the operation inside clearly monitored, Signal switch on the top of the door avoid possible injury to the operator.

6. Energy saving and interrupted system for the washing machine.

7. Unique water nozzle design makes the maintenance easy and fast.

8. Heating system for the water and blowing air. Start it when the ambient temperature no more than 7 degree.

9. Automatic control 6 brushers for Glass.

10. There is a special system for Producing triple insulating glass.

11. Having a system for the wrong operation and automatically wait for the second glass following.

12. Automatic assembly inside the press machine.

13. High-class casting and processing of spare parts assure good stability of the line.

14. The key connections use expanded joint instead of common union. This guarantees high adjustment precision and conveying reliability.

*20years factory production experience*3 years machine warranty

*156 exported country experience

*20000 square meters Glass machine&upvc windows machine factory

*Shandong Eworld Machine Co., Ltd.

Shandong Eworld Machine Co., Ltd. is one of the famous and big manufacturers of glass equipment, windows equipment, CNC equipment.

Since its inception in 2002, and after many years of development and growth, the company is now playing a leading role in glass machinery and windows door machine inChina Eworld group has 2 factories, which are located in Jinan City. Advanced products, exquisite techniques, solid working, and cordial services

We went to many exhibitions in China to expand our reputation.

Welcome to visit our factory!If you have plan to come to China and see our machines, please contact us at least 15 days in advance

then we can arrange our

schedule and arrange to treat you.

No matter which transport method you choose, we will pick up you.

If you have any questions, please feel free to contact us.

24*7, we always be here !

FAQ

Question:Are you manufacture?

Answer:Yes,we are the professional manufacture which have more than 5 workshops.

Question: How about the service ?

Answer:

1).reply it at once if from Ali-trademanager,if by email,it reply it within 12 hour

2).deliver max. days within 15 days

3).24 hours for after -sale serive

4).more than 12 years experience in this kind machine field

5).fluent english ,communication barrier free

Question:What’s the guarantee ?

Answer:

1).Our guarantee for 18 months.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).2 year quality guaranty for the machine (excluding the consumables)

5).We will provide the consumable parts at an agency price

6).24 hours on line service each day, free technical support.

Q: Do you provide equipment operation training?

Answer:Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. Allof our engineers have passport.

Question:if our price is higher than another company or factories ?

Answer:please check, what is is the different of the machine parts ,service and guarantee,especially the machine inner electric parts,sometimes, if machines have breakdown, the most reason is the machine inner electric parts problem, but we use the famous andreliable parts for the machines inside.

Question:How long is the delivery time ?

Answer:For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients specific requirements, it would be 15 to 30 days.

Question: What is the payment ?

Answer:Any payment method you want,such as L/C,T/T,D/P,West-union and so on.

The glass insulating production line will be put in a wooden case and has a seaworthy package. Shipping product within 20-25days after receipt of the buyer's 30% deposit.

The glass insulating production line will be put in a wooden case and has a seaworthy package. Shipping product within 20-25days after receipt of the buyer's 30% deposit.

1. Our Goal

Eworld Machine Co., Ltd provides full set services and high-quality but low-price products. We are always looking for long-term cooperation, not a one-time deal.

2. Pre-sale

Eworld provides 24 hours high-quality service. When clients contact Eworld and ask for products, E-World answers at once, except our clerk's sleep, which condition we answer within 10hours. Eworld understands how important it is for the customers to choose a suitable machine, we are ready to come up with the best solution for customers.

3. On-sale

For all your requests, we will supply the best solution to you as soon as possible. If you have any inquiries or problems, please contact us with E-mail, skype, Alibaba, WhatsApp, phone, etc.

Eworld welcome customers to visit the factory, we will pick you up from the airport or train station. Eworld location is convenient to welcome clients because of next to the train station.

4. After-sale service

When customers buy the glass insulating production line, E-World promises that the machine will be delivered in 20-25 days after deposit. E-World arranges commodity packages suitable for the shipment of sea. E-World provides English instruction about manual guide and video technical support. Any problems please let us know, and we will give you detailed support and advice. E-World promises worry-free repair of one whole year after installation, the original fault parts damaged, be free of any charges. When a serious breakdown and big fault happens, E-World has engineered and they can fly there to solve it.

FAQ

Frequently Questions

1. Question: Are you manufacture?

Answer:

Yes, we are professional manufacture which has more than 5 workshops.

2. Question: How about the service?

Answer:

1). reply it at once if from Ali-trademanager if by email, it reply it within 12 hour

2). deliver max. days within 15 days

3). 24 hours for after-sale service

4). more than 12 years experience in this kind of machine field

5). fluent English,communication barrier-free

3. Question: What’s the guarantee?

Answer:

1). Our guarantee for 18 months.

2). 24 hour’s technical support by email or calling

3). English manual and video tutorial

4). 2 year quality guaranty for the machine (excluding the consumables)

5). We will provide the consumable parts at an agency price

6). 24 hours online service each day, free technical support.

4. Question: Do you provide equipment operation training?

Answer:

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

5. Question: if our price is higher than another company or factories?

Answer:

Please check, what is the difference of the machine parts, service and guarantee, especially the machine inner electric parts, sometimes, if machines have a breakdown, the most reason is the machine inner electric parts problem, but we use the famous and reliable parts for the machines inside.

6. Question: How long is the delivery time?

Answer:

For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients' specific requirements, it would be 15 to 30 days.

7. Question: What is the payment?

Answer:

Any payment method you want, such as L/C, T/T, D/P, West-union and so on.

1. Our Goal

Eworld Machine Co., Ltd provides full set services and high-quality but low-price products. We are always looking for long-term cooperation, not a one-time deal.

2. Pre-sale

Eworld provides 24 hours high-quality service. When clients contact Eworld and ask for products, E-World answers at once, except our clerk's sleep, which condition we answer within 10hours. Eworld understands how important it is for the customers to choose a suitable machine, we are ready to come up with the best solution for customers.

3. On-sale

For all your requests, we will supply the best solution to you as soon as possible. If you have any inquiries or problems, please contact us with E-mail, skype, Alibaba, WhatsApp, phone, etc.

Eworld welcome customers to visit the factory, we will pick you up from the airport or train station. Eworld location is convenient to welcome clients because of next to the train station.

4. After-sale service

When customers buy the glass insulating production line, E-World promises that the machine will be delivered in 20-25 days after deposit. E-World arranges commodity packages suitable for the shipment of sea. E-World provides English instruction about manual guide and video technical support. Any problems please let us know, and we will give you detailed support and advice. E-World promises worry-free repair of one whole year after installation, the original fault parts damaged, be free of any charges. When a serious breakdown and big fault happens, E-World has engineered and they can fly there to solve it.

FAQ

Frequently Questions

1. Question: Are you manufacture?

Answer:

Yes, we are professional manufacture which has more than 5 workshops.

2. Question: How about the service?

Answer:

1). reply it at once if from Ali-trademanager if by email, it reply it within 12 hour

2). deliver max. days within 15 days

3). 24 hours for after-sale service

4). more than 12 years experience in this kind of machine field

5). fluent English,communication barrier-free

3. Question: What’s the guarantee?

Answer:

1). Our guarantee for 18 months.

2). 24 hour’s technical support by email or calling

3). English manual and video tutorial

4). 2 year quality guaranty for the machine (excluding the consumables)

5). We will provide the consumable parts at an agency price

6). 24 hours online service each day, free technical support.

4. Question: Do you provide equipment operation training?

Answer:

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

5. Question: if our price is higher than another company or factories?

Answer:

Please check, what is the difference of the machine parts, service and guarantee, especially the machine inner electric parts, sometimes, if machines have a breakdown, the most reason is the machine inner electric parts problem, but we use the famous and reliable parts for the machines inside.

6. Question: How long is the delivery time?

Answer:

For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients' specific requirements, it would be 15 to 30 days.

7. Question: What is the payment?

Answer:

Any payment method you want, such as L/C, T/T, D/P, West-union and so on.

Eworld Machine's product

Eworld, best supplier in China.

In the 2001 year we started to do trade in the domestic market, 11 years of international trade experience, 2014 year we have Shandong Eworld Machine CO., LTD. Now we have mature experience and boomy develop. For example, Just from the 2019 year to the 2020 year, we have 180 transactions, 2.5 Million Us dollar turnover. This is our official English website: eworldmachine.en.

We have been a high and new technology enterprise specializing in developing, empoldering, and selling a series of CNC automatic glass machines, glass deep processing machines, window machines, and door machines for many years.

Main products: automatic insulating glass production line, glass washing and drying machines, Automatic glass cutting machines, Glass edging machine, Glass lifting machines, Automatic EVA/PVB Laminated glass production lines, CNC processing center, Glass drilling machine, Glass sandblaster, Glass screen printing machine, Aluminum/PVC UPVC profile window door machines.

Advanced products, exquisite techniques, solid working, and cordial services all give birth to the unique culture of EWORLD today. EWORLD always keeps step on the latest technology and is committed to providing the most advanced products for our customers. Moreover, EWORLD always emphasizes the training and quality of our staff.

During recent years, our company has taken "customer the highest, technique the first, service following" as our notion, "to be the most customer-oriented and service-aware" as our task and "let customer fully know and select the suitable glass processing machines they need.

Eworld Machine's product

Eworld, best supplier in China.

In the 2001 year we started to do trade in the domestic market, 11 years of international trade experience, 2014 year we have Shandong Eworld Machine CO., LTD. Now we have mature experience and boomy develop. For example, Just from the 2019 year to the 2020 year, we have 180 transactions, 2.5 Million Us dollar turnover. This is our official English website: eworldmachine.en.

We have been a high and new technology enterprise specializing in developing, empoldering, and selling a series of CNC automatic glass machines, glass deep processing machines, window machines, and door machines for many years.

Main products: automatic insulating glass production line, glass washing and drying machines, Automatic glass cutting machines, Glass edging machine, Glass lifting machines, Automatic EVA/PVB Laminated glass production lines, CNC processing center, Glass drilling machine, Glass sandblaster, Glass screen printing machine, Aluminum/PVC UPVC profile window door machines.

Advanced products, exquisite techniques, solid working, and cordial services all give birth to the unique culture of EWORLD today. EWORLD always keeps step on the latest technology and is committed to providing the most advanced products for our customers. Moreover, EWORLD always emphasizes the training and quality of our staff.

During recent years, our company has taken "customer the highest, technique the first, service following" as our notion, "to be the most customer-oriented and service-aware" as our task and "let customer fully know and select the suitable glass processing machines they need.

Eworld Machine's product

Eworld, best supplier in China.

In the 2001 year we started to do trade in the domestic market, 11 years of international trade experience, 2014 year we have Shandong Eworld Machine CO., LTD. Now we have mature experience and boomy develop. For example, Just from the 2019 year to the 2020 year, we have 180 transactions, 2.5 Million Us dollar turnover. This is our official English website: eworldmachine.en.

We have been a high and new technology enterprise specializing in developing, empoldering, and selling a series of CNC automatic glass machines, glass deep processing machines, window machines, and door machines for many years.

Main products: automatic insulating glass production line, glass washing and drying machines, Automatic glass cutting machines, Glass edging machine, Glass lifting machines, Automatic EVA/PVB Laminated glass production lines, CNC processing center, Glass drilling machine, Glass sandblaster, Glass screen printing machine, Aluminum/PVC UPVC profile window door machines.

Advanced products, exquisite techniques, solid working, and cordial services all give birth to the unique culture of EWORLD today. EWORLD always keeps step on the latest technology and is committed to providing the most advanced products for our customers. Moreover, EWORLD always emphasizes the training and quality of our staff.

During recent years, our company has taken "customer the highest, technique the first, service following" as our notion, "to be the most customer-oriented and service-aware" as our task and "let customer fully know and select the suitable glass processing machines they need.

Eworld Machine's product

Eworld, best supplier in China.

In the 2001 year we started to do trade in the domestic market, 11 years of international trade experience, 2014 year we have Shandong Eworld Machine CO., LTD. Now we have mature experience and boomy develop. For example, Just from the 2019 year to the 2020 year, we have 180 transactions, 2.5 Million Us dollar turnover. This is our official English website: eworldmachine.en.

We have been a high and new technology enterprise specializing in developing, empoldering, and selling a series of CNC automatic glass machines, glass deep processing machines, window machines, and door machines for many years.

Main products: automatic insulating glass production line, glass washing and drying machines, Automatic glass cutting machines, Glass edging machine, Glass lifting machines, Automatic EVA/PVB Laminated glass production lines, CNC processing center, Glass drilling machine, Glass sandblaster, Glass screen printing machine, Aluminum/PVC UPVC profile window door machines.

Advanced products, exquisite techniques, solid working, and cordial services all give birth to the unique culture of EWORLD today. EWORLD always keeps step on the latest technology and is committed to providing the most advanced products for our customers. Moreover, EWORLD always emphasizes the training and quality of our staff.

During recent years, our company has taken "customer the highest, technique the first, service following" as our notion, "to be the most customer-oriented and service-aware" as our task and "let customer fully know and select the suitable glass processing machines they need.