WhatsApp: +8615665767071 Email: info@eworldmachine.com

WD-1830

Eworld

8475291900

| Availability: | |

|---|---|

| Quantity: | |

Cnc Edging Polishing Milling Glass Cutting Machine

Main Application

Cnc Edging Polishing Milling Glass Cutting Machine ,Drilling, Milling, Internal and External grinding and polishing, Writing, Shaped Notching, Engraving on glass、Marable, stone, quartz and so on

Mechanic Structure

1.The machine tool and beam adopt welded steel structure. With special heat treatment, the structure is firm and can work for a long time.

2.The machine uses automobile paint which is more rust-resistant.

3.Total weight: about 7 tons (including peripheral accessories and electric cabinet).

Mechanic Transmission

The machine is transmitted through AC servo motor by synchronic belt and synchronic belt wheel driven spindle. There is automatic lubricating system for the screw nut and guide-rail slider of the transmitting parts.

Servo System

It adopts Mitsubishi/Hitachi AC servo system

Screw: all the screws are from KGF series double nut screw (German NEFF)

Worktable

1.There is a multi-location worktable of large size in front of the machine. With function of automatic rubdown of high precision, users can adjust the flatness of the worktable when needed. This is to keep a flat worktable.

2.There are positioning blocks for the work piece and vacuum system.

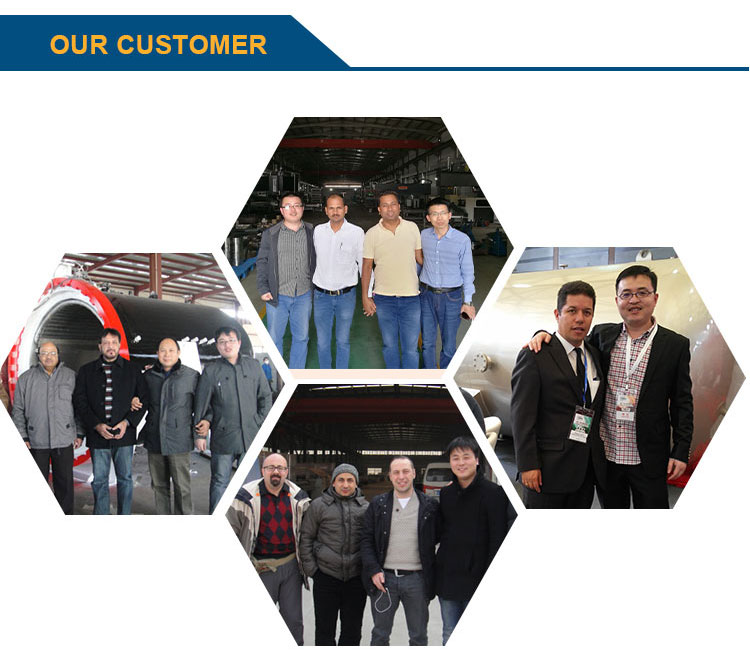

3.There is a tool library with 2 x 5 tools. There is a tool library with 5 tools at both left and right side of the machine. Users can select different tools and optimize route according to processing requirements.

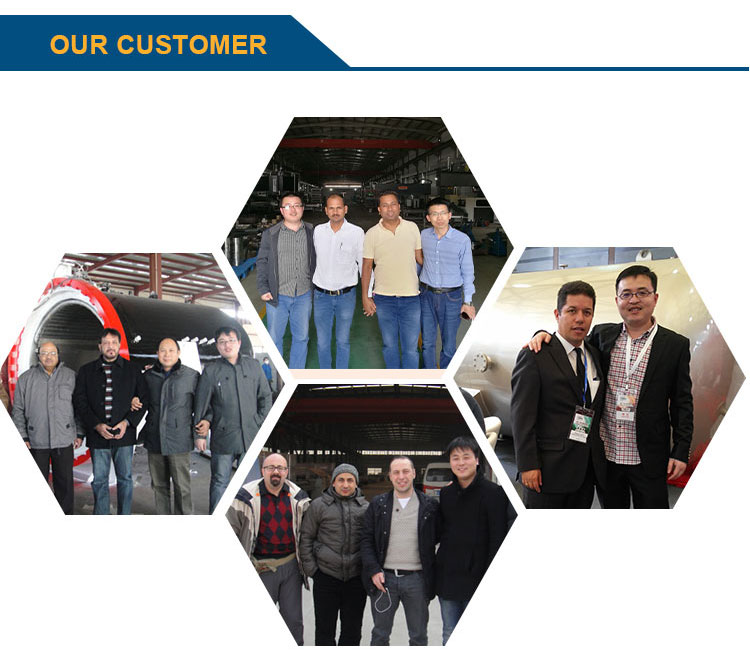

Parts of Main Spindle

1.Motor of the main spindle: it adopts asynchronous speed-adjust sensor motor of high efficiency. Adjusting range of rotating speed: 0 – 9000.

2.The machine equips 10 pieces of IOS 40 handles. The cone part adopts 7:24 international uniform standard which is easy to be changed. Grinding wheel with outer diameter 170 mm can be used.

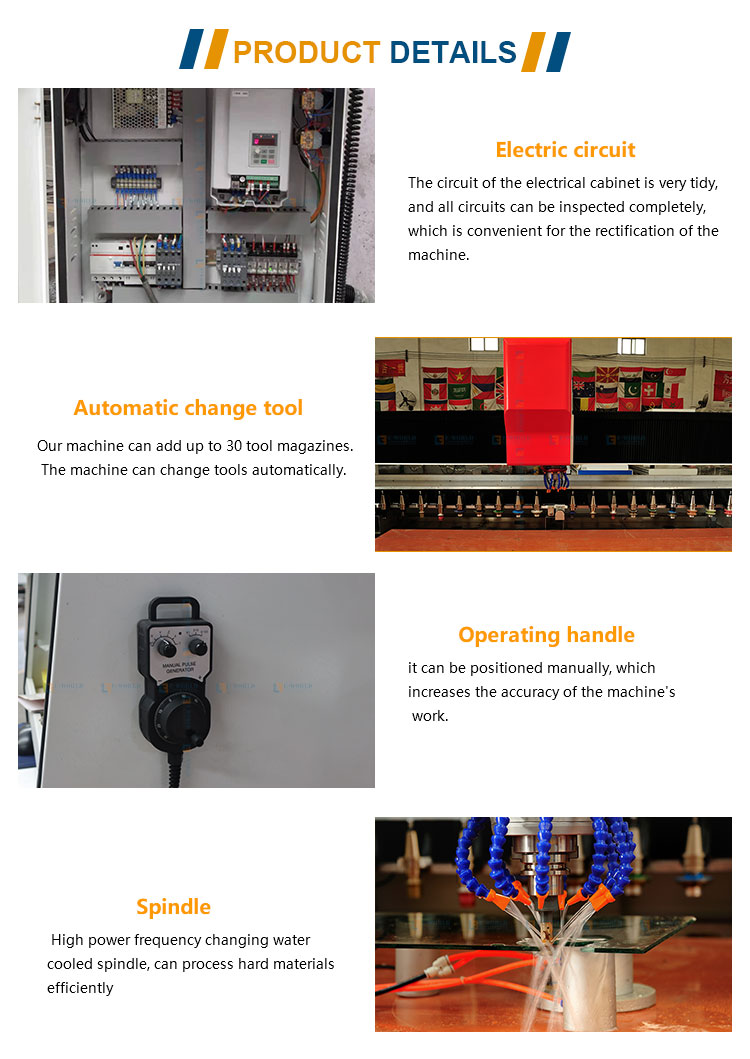

Electric Cabinet

The distributing of electric cabinet can be designed according to customer’s requirements. Each terminal is clearly marked. This is convenient for the maintenance in the future.

Drawing Software

With Auto CAD software, user can design any geometrical pattern on PC with mouse and keyboard.

Typesetting System

With combination of CNC engraving system, user can set the variable parameter of processing pattern and then it will generate G code automatically.

Safety and Reliability of Operation

1.The moving parts are lubricated by automatic lubricating system.

2. Electric cabinet adopts IP54 industrial standard and equips air-conditioner.

3.The electric parts inside electric cabinet are common products in the market which is easily changed.

4.The main fault will be automatically reminded.

Central Lubricating System

It adopts PDI lubricating system of American BIJUR – DELIMON which can timely lubricate the transmitting parts by separate setting to PLC.

Configure of Machine

1.Handle: 10 pieces of IOS 40 handles (it equips 10 pieces of grinding wheels. Amount can be changed according to customer’s requirement).

2.Motor of main spindle: 6 KW

3.Vacuum pump: vacuum for sucking raw glass

4.Placing of electric cabinet: length-ways/transverse; length-ways

Main technical data

Transverse | axis XX = 3000 mm |

Length ways | axis Y: Y = 1800 mm |

Vertical | axis Z: Z = 250 mm |

Allocating accuracy(X,Y,Z) | 0.01*002*0.01 |

Speed(X,Y) | 5m/minute |

Running Condition

Power supply | 380 V, 50 Hz, 3 phases |

Environment temperature | 0 – 50 ℃ |

Relative humidity | < 90% |

Compressed air | ≥ 0.6 Mpa |

*20years factory production experience*3 years machine warranty

*156 exported country experience

*20000 square meters Glass machine&upvc windows machine factory

*Shandong Eworld Machine Co., Ltd.

Shandong Eworld Machine Co., Ltd. is one of the famous and big manufacturers of glass equipment, windows equipment, CNC equipment.

Since its inception in 2002, and after many years of development and growth, the company is now playing a leading role in glass machinery and windows door machine inChina Eworld group has 2 factories, which are located in Jinan City. Advanced products, exquisite techniques, solid working, and cordial services

About glass deep processing machines, we are professional and have full set certificates.For every glass cutting machine, we have

serious quality control for every machine and every parts before it leaves our factory.

We went to many exhibitions in China to expand our reputation.

Welcome to visit our factory!If you have plan to come to China and see our machines, please contact us at least 15 days in advance

then we can arrange our

schedule and arrange to treat you.

No matter which transport method you choose, we will pick up you.

If you have any questions, please feel free to contact us.

24*7, we always be here !

FAQ

Question:Are you manufacture?

Answer:Yes,we are the professional manufacture which have more than 5 workshops.

Question: How about the service ?

Answer:

1).reply it at once if from Ali-trademanager,if by email,it reply it within 12 hour

2).deliver max. days within 15 days

3).24 hours for after -sale serive

4).more than 12 years experience in this kind machine field

5).fluent english ,communication barrier free

Question:What’s the guarantee ?

Answer:

1).Our guarantee for 18 months.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).2 year quality guaranty for the machine (excluding the consumables)

5).We will provide the consumable parts at an agency price

6).24 hours on line service each day, free technical support.

Q: Do you provide equipment operation training?

Answer:Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. Allof our engineers have passport.

Question:if our price is higher than another company or factories ?

Answer:please check, what is is the different of the machine parts ,service and guarantee,especially the machine inner electric parts,sometimes, if machines have breakdown, the most reason is the machine inner electric parts problem, but we use the famous andreliable parts for the machines inside.

Question:How long is the delivery time ?

Answer:For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients specific requirements, it would be 15 to 30 days.

Question: What is the payment ?

Answer:Any payment method you want,such as L/C,T/T,D/P,West-union and so on.

Cnc Edging Polishing Milling Glass Cutting Machine

Main Application

Cnc Edging Polishing Milling Glass Cutting Machine ,Drilling, Milling, Internal and External grinding and polishing, Writing, Shaped Notching, Engraving on glass、Marable, stone, quartz and so on

Mechanic Structure

1.The machine tool and beam adopt welded steel structure. With special heat treatment, the structure is firm and can work for a long time.

2.The machine uses automobile paint which is more rust-resistant.

3.Total weight: about 7 tons (including peripheral accessories and electric cabinet).

Mechanic Transmission

The machine is transmitted through AC servo motor by synchronic belt and synchronic belt wheel driven spindle. There is automatic lubricating system for the screw nut and guide-rail slider of the transmitting parts.

Servo System

It adopts Mitsubishi/Hitachi AC servo system

Screw: all the screws are from KGF series double nut screw (German NEFF)

Worktable

1.There is a multi-location worktable of large size in front of the machine. With function of automatic rubdown of high precision, users can adjust the flatness of the worktable when needed. This is to keep a flat worktable.

2.There are positioning blocks for the work piece and vacuum system.

3.There is a tool library with 2 x 5 tools. There is a tool library with 5 tools at both left and right side of the machine. Users can select different tools and optimize route according to processing requirements.

Parts of Main Spindle

1.Motor of the main spindle: it adopts asynchronous speed-adjust sensor motor of high efficiency. Adjusting range of rotating speed: 0 – 9000.

2.The machine equips 10 pieces of IOS 40 handles. The cone part adopts 7:24 international uniform standard which is easy to be changed. Grinding wheel with outer diameter 170 mm can be used.

Electric Cabinet

The distributing of electric cabinet can be designed according to customer’s requirements. Each terminal is clearly marked. This is convenient for the maintenance in the future.

Drawing Software

With Auto CAD software, user can design any geometrical pattern on PC with mouse and keyboard.

Typesetting System

With combination of CNC engraving system, user can set the variable parameter of processing pattern and then it will generate G code automatically.

Safety and Reliability of Operation

1.The moving parts are lubricated by automatic lubricating system.

2. Electric cabinet adopts IP54 industrial standard and equips air-conditioner.

3.The electric parts inside electric cabinet are common products in the market which is easily changed.

4.The main fault will be automatically reminded.

Central Lubricating System

It adopts PDI lubricating system of American BIJUR – DELIMON which can timely lubricate the transmitting parts by separate setting to PLC.

Configure of Machine

1.Handle: 10 pieces of IOS 40 handles (it equips 10 pieces of grinding wheels. Amount can be changed according to customer’s requirement).

2.Motor of main spindle: 6 KW

3.Vacuum pump: vacuum for sucking raw glass

4.Placing of electric cabinet: length-ways/transverse; length-ways

Main technical data

Transverse | axis XX = 3000 mm |

Length ways | axis Y: Y = 1800 mm |

Vertical | axis Z: Z = 250 mm |

Allocating accuracy(X,Y,Z) | 0.01*002*0.01 |

Speed(X,Y) | 5m/minute |

Running Condition

Power supply | 380 V, 50 Hz, 3 phases |

Environment temperature | 0 – 50 ℃ |

Relative humidity | < 90% |

Compressed air | ≥ 0.6 Mpa |

*20years factory production experience*3 years machine warranty

*156 exported country experience

*20000 square meters Glass machine&upvc windows machine factory

*Shandong Eworld Machine Co., Ltd.

Shandong Eworld Machine Co., Ltd. is one of the famous and big manufacturers of glass equipment, windows equipment, CNC equipment.

Since its inception in 2002, and after many years of development and growth, the company is now playing a leading role in glass machinery and windows door machine inChina Eworld group has 2 factories, which are located in Jinan City. Advanced products, exquisite techniques, solid working, and cordial services

About glass deep processing machines, we are professional and have full set certificates.For every glass cutting machine, we have

serious quality control for every machine and every parts before it leaves our factory.

We went to many exhibitions in China to expand our reputation.

Welcome to visit our factory!If you have plan to come to China and see our machines, please contact us at least 15 days in advance

then we can arrange our

schedule and arrange to treat you.

No matter which transport method you choose, we will pick up you.

If you have any questions, please feel free to contact us.

24*7, we always be here !

FAQ

Question:Are you manufacture?

Answer:Yes,we are the professional manufacture which have more than 5 workshops.

Question: How about the service ?

Answer:

1).reply it at once if from Ali-trademanager,if by email,it reply it within 12 hour

2).deliver max. days within 15 days

3).24 hours for after -sale serive

4).more than 12 years experience in this kind machine field

5).fluent english ,communication barrier free

Question:What’s the guarantee ?

Answer:

1).Our guarantee for 18 months.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).2 year quality guaranty for the machine (excluding the consumables)

5).We will provide the consumable parts at an agency price

6).24 hours on line service each day, free technical support.

Q: Do you provide equipment operation training?

Answer:Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. Allof our engineers have passport.

Question:if our price is higher than another company or factories ?

Answer:please check, what is is the different of the machine parts ,service and guarantee,especially the machine inner electric parts,sometimes, if machines have breakdown, the most reason is the machine inner electric parts problem, but we use the famous andreliable parts for the machines inside.

Question:How long is the delivery time ?

Answer:For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients specific requirements, it would be 15 to 30 days.

Question: What is the payment ?

Answer:Any payment method you want,such as L/C,T/T,D/P,West-union and so on.