WhatsApp: +8615665767071 Email: info@eworldmachine.com

WL2500

Eworld

| Availability: | |

|---|---|

| Quantity: | |

1.Glass washing and drying machine:

The washer drier, with digital display, can automatically regulate the rising and descending of the upper rubber roller, hair brush roller and air knife according to the glass thickness. The upper part can be raised to 400mm on the whole for being easy to clean and maintain. The hair brush roller is driven by two motors in the upper and lower part respectively. It is equipped with two pairs of stainless air knives and the blower owns silencer cotton and air intake filter and has features of great air quantity, low noise and good air-dry effect.

2.1. Max glass width: 2500mm

2.2. Minimum glass specification:420×350mm

2.3.Glass thickness 3-25mm,CNC auto-adjustment.

2.4.Glass conveying Speed from 0.5~4 m/min,adjustable.

2.5. Speed control method: frequency control

2.6. Outer dimension: 6300×3000×1650mm

2.7. Table height of roller: 810mm

2.8. Total power: 39KW

2.9. Water source: self-loop, supplemented by tapping pipe

2.10.Power:380VAC,50Hz

2.11. Weight: 3000Kg

2.2. Structural features

2.2.1. Hair brush roller: three pairs in total.

2.2.2. The metal parts in cleaning section contacting with water are stainless materials. The water supply system is PVC plastic pipe.

2.2.3. Cleaning section, cooling section and the outer cover of the lower section are cold-plate painting.

2.2.4. The cleaning section and air drying section can be raised by 400 mm. on the whole for being easy to clean and maintain.

2.2.5. The lifting drive shaft is optical axis painting.

2.Glass assemble machine

3.1glass walking sucker hanger

It’s composed of machine body、vacuum system、walking system、pneumatic raise-drop system and control system.the haptor moving is driven by the cylinder. It’s featured with clean environment and no pollution..the accuracy can be≤±1mm.

3.1.1. walking speed: 4m/min

3.1.2.Max sucking weight:1200kg

3.1.3. glass size:3600mm× 2500mm

3.1.4. Outer dimension:2500 × 1500 × 1700mm

3.1.5.motor power:0.37KW

3.1.6.Power:AC380V,50Hz

3.1.7.Air source:Pressure 0.5~0. 8Mpa, flow capacity 6.3L/min

3.1.8.Weight:1200Kg

3.2Transitional conveyor

3.2.1.Conveying speed:0.25~5m/min

3.2.2. Speed control method: frequency conversion

3.2.3.Conveyor motor power: 1.1KW

3.2.4.Outer dimension:2500 X 1600 X 810mm

3.2.5.Power:AC380V,50Hz, pressure :0.5-0.8mpa

3.2.6. Weight: 1100Kg

4.1. Automatic PVB Putting Machine

three-volume of PVB film automatic transposition independent by motor control,the power of the motor is 0.75 kw.

4.1. Quantity of PVB film to hold: 3 rolls

4.2.Rotation pattern of PVB film : manual

4.3. Outer dimension: 2000×3920×2400mm

4.4. Table height of roller: 860mm

4.5. Weight: 680Kg

3.Pre-heating and pre-press machine

The roller press is used for flat and laminated glass and multilayer combination of bulletproof glass consisting of top segment,prepress,heating up,final press and off-loading section. At the same time ,It’s able to instead of the pre-pressing and heating-pressing machine of the hollow glass production line .the machin has PLC touch cabinet and one –button start.,adjust the pressure from 0 to 0.6mpa according to the glass thickness and area.

5.1. Technical parameters

5.1.1. Max glass width: 2500mm

5.1.2. Min glass width: 300mm

5.1.3. test and adjust the glass thickness full-autimatically

5.1.4. gear box is made of 10mm steel plate.

5.1.5. Processed glass thickness: 4~65mm

5.1.6. Stage level of roller: 860mm

5.1.7.Conveying speed:0~400m/min (frequency conversion ajustable )

5.1.8. there’s two sections of the heating part ,the total height is 4.6m,each section is 2.3m. there are 60 infrared heating elements and stainless steel reflector panel,the heating room is covered with Silicon cotton and protect by galvanized iron sheets .

5.1.9. Total power: 63KW, heating power:62kw, transmission power:1.1kw

5.1.10.Power:AC380V,50Hz

5.1.11. Speed control method: frequency conversion

5.1.12. Weight: 4500Kg

5.2. Structural features

5.2.1. The outer cover is cold plate painting.

5.2.2. The promotion structure is made of screw ,linear shaft ,angular tooth ,electrical cylinder

5.2.3. Structure of roller :top grade rubber roller of high temperature and aging resistant

4.Glass autoclave

The infrared autoclave fits to manufacture curved and flat laminated glass ---architectural laminated glass, automative glass and bullet proof glass. The installed power of infrared autoclave is 50% less than existing autoclave and its energy-saving 30-40% .We also offer following glass laminating line machines: glass loading、 glass off-loading、glass washing and drying, assembly room,over-head vacaum lift,transfer unit and positioning station , IR preheat oven and presser, autoclave-car and PVB interlayers for laminated glass.

The infared autoclave adopt the design of a new train of thought, namely,make use of the natural forces and function of complex ways, greatly reducing the installation power and create the conditions for highly efficient heating method ..

The central technology of Autoclave is the circulatory system and match heating system, which used the world's first natural cycle structure, heating and pressure power even cooling power and cycle power coincide, so that air can be natural circulation when heating and cooling; wavelength matches the heating system in accordance with the principle of selection of a specific wavelength of infrared transparent gold-plated heating tube ,can be reached the high efficiency of heating and absorption of glass.

Furthermore, infrared autoclave cooling system and control system of technological innovation: the cooling system uses hot-dip galvanizing finned tube seamless steel pipe,with descaling and anti-scaling technology, non-scaling and does not rust; control system adopted optimized process curve, the exhaust from working to the end is one-touch, high degree of automation, to avoid the impact of the quality by the uneven level of the operator. Practicable technical won’t make fire for the autoclave without air steam

Specifically,there’s some merits as followings

1.low power,high efficiency,and noticeable energy saving

The working time of Infared autoclave is less than or basically the same as the traditional autoclave, but only half of its installation power or even lower. Autoclave of dia2650 * 5500mm only 86KW, Autoclave of dia 2650 * 6000mm only 92KW, dia2850 * 6000mm only 102KW, dia3000 * 8000mm only 144KW. compared with the traditional autoclave ,The installation of the infared one is reduced nearly 50%,more than 30-40% of energy saving,

2.appropriate circulation ,temperature uniformity. The highest temperature is always controlled at less than 130 ℃

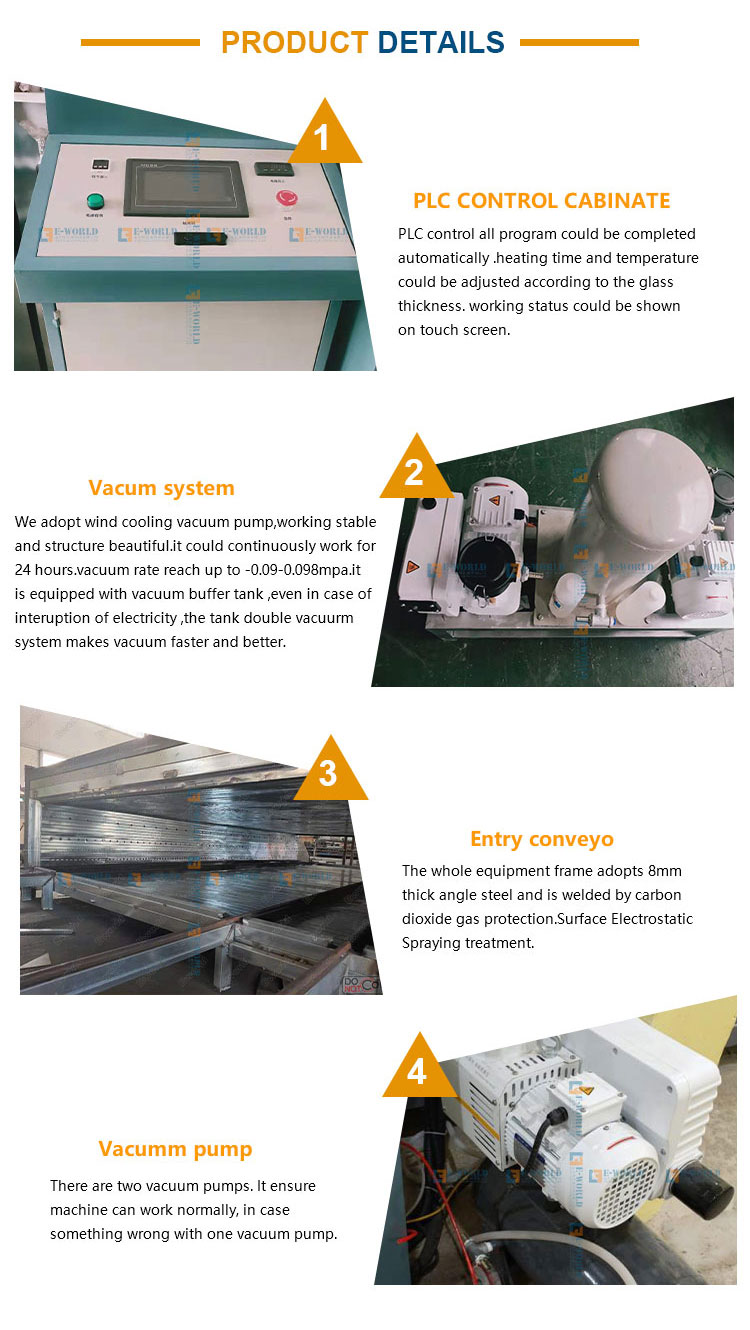

3.PLC+ touch screen system and one-touch complete, High automation degree.

Cooling system equiped with descaling and anti-scaling technology, non-scaling and does not rust

Practicable technical won’t catch fire for the autoclave without air steam

6. no noise and no oil pollution, so that to achieve clean and civilized production workshop

The quality of Autoclave depends on four aspects:

1. the quality (good or bad) of autoclave body itself: there’s no problem with the pressure of the body, the key is the quality of autoclave door flange and solid and smart of opening the door or not. Ours is a steel forging of the flange which is the best in china, the door device (as the picture shows ) is not only solid, and easy to adjust, although 1 ton heavier than 1 ton of others, but easy to use, long-term deformation. Adjustment easily switches by a person. Many autoclave door of other manufacturers is deformation after a period of time, brought many troubles to the customers.

2. technology of autoclave is advanced or not: depend on two aspects, first, energy-saving or not, the second is whether the uniform temperature.

3. water-cooled system and the life of the heating tube: Cooling water pipe leaks and heating tube is short-life, they are a common problem in many autoclave. the cooling system of infrared autoclave adopts finned tube seamless steel pipe and hot-dip zinc processing, non-scaling and does not rust,the life is several times more than ordinary zinc pipe ; infrared heating tube is gold-plated tube, it is not only high efficient, but also long life, there are several times more than the ordinary white quartz heating tube.

4 . Control system: The good control system must be the craft optimization product qualified rate is high, simultaneously the automaticity is high, the operation is simple, cannot operate each kind of pressed key's control system frequently. The infrared autoclave’s control system unified key starts, the entire journey automation, saves the person convenient qualified rate to be high. Has avoided the operators level irregularly to the product quality influence. The practical and feasible technological means will cause the autoclavenot to need to steam spatially will not catch fire

Main configuration of the equipment

PLC control system 1 set

Autoclave body 1 piece

Autoclave door 1 set

Motor 2 sets

Heater 1 set

Cooler 1 set

Electric control cabinet 1 set

Safety valve 2 pieces

Pressure gauge 1 piece

Spare parts (tool) 1 set

Main technical parameters of the equipment

No. | Content | Technical parameter |

1 | Design pressure | 1.5MPa |

2 | Working pressure | 1.2-1.3 MPa |

3 | Design temperature | 150℃ |

4 | Working temperature | 120-130℃ |

5 | Working medium | Compressed air |

6 | Popping pressure of safety valve | 1.4 MPa |

7 | 102KW | |

9 | Heating method | a specific wavelength of transparent gold-plated infrared heating tube |

10 | Temperature and pressure control method | PLC |

11 | Length | 6000mm |

12 | 2650mm |

*20years factory production experience*3 years machine warranty

*156 exported country experience

*20000 square meters Glass machine&upvc windows machine factory

*Shandong Eworld Machine Co., Ltd.

Shandong Eworld Machine Co., Ltd. is one of the famous and big manufacturers of glass equipment, windows equipment, CNC equipment.

Since its inception in 2002, and after many years of development and growth, the company is now playing a leading role in glass machinery and windows door machine inChina Eworld group has 2 factories, which are located in Jinan City. Advanced products, exquisite techniques, solid working, and cordial services

About glass deep processing machines, we are professional and have full set certificates.For every glass cutting machine, we have

serious quality control for every machine and every parts before it leaves our factory.

We went to many exhibitions in China to expand our reputation.

Welcome to visit our factory!If you have plan to come to China and see our machines, please contact us at least 15 days in advance

then we can arrange our

schedule and arrange to treat you.

No matter which transport method you choose, we will pick up you.

If you have any questions, please feel free to contact us.

24*7, we always be here !

FAQ

Question:Are you manufacture?

Answer:Yes,we are the professional manufacture which have more than 5 workshops.

Question: How about the service ?

Answer:

1).reply it at once if from Ali-trademanager,if by email,it reply it within 12 hour

2).deliver max. days within 15 days

3).24 hours for after -sale serive

4).more than 12 years experience in this kind machine field

5).fluent english ,communication barrier free

Question:What’s the guarantee ?

Answer:

1).Our guarantee for 18 months.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).2 year quality guaranty for the machine (excluding the consumables)

5).We will provide the consumable parts at an agency price

6).24 hours on line service each day, free technical support.

Q: Do you provide equipment operation training?

Answer:Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. Allof our engineers have passport.

Question:if our price is higher than another company or factories ?

Answer:please check, what is is the different of the machine parts ,service and guarantee,especially the machine inner electric parts,sometimes, if machines have breakdown, the most reason is the machine inner electric parts problem, but we use the famous andreliable parts for the machines inside.

Question:How long is the delivery time ?

Answer:For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients specific requirements, it would be 15 to 30 days.

Question: What is the payment ?

Answer:Any payment method you want,such as L/C,T/T,D/P,West-union and so on.

1.Glass washing and drying machine:

The washer drier, with digital display, can automatically regulate the rising and descending of the upper rubber roller, hair brush roller and air knife according to the glass thickness. The upper part can be raised to 400mm on the whole for being easy to clean and maintain. The hair brush roller is driven by two motors in the upper and lower part respectively. It is equipped with two pairs of stainless air knives and the blower owns silencer cotton and air intake filter and has features of great air quantity, low noise and good air-dry effect.

2.1. Max glass width: 2500mm

2.2. Minimum glass specification:420×350mm

2.3.Glass thickness 3-25mm,CNC auto-adjustment.

2.4.Glass conveying Speed from 0.5~4 m/min,adjustable.

2.5. Speed control method: frequency control

2.6. Outer dimension: 6300×3000×1650mm

2.7. Table height of roller: 810mm

2.8. Total power: 39KW

2.9. Water source: self-loop, supplemented by tapping pipe

2.10.Power:380VAC,50Hz

2.11. Weight: 3000Kg

2.2. Structural features

2.2.1. Hair brush roller: three pairs in total.

2.2.2. The metal parts in cleaning section contacting with water are stainless materials. The water supply system is PVC plastic pipe.

2.2.3. Cleaning section, cooling section and the outer cover of the lower section are cold-plate painting.

2.2.4. The cleaning section and air drying section can be raised by 400 mm. on the whole for being easy to clean and maintain.

2.2.5. The lifting drive shaft is optical axis painting.

2.Glass assemble machine

3.1glass walking sucker hanger

It’s composed of machine body、vacuum system、walking system、pneumatic raise-drop system and control system.the haptor moving is driven by the cylinder. It’s featured with clean environment and no pollution..the accuracy can be≤±1mm.

3.1.1. walking speed: 4m/min

3.1.2.Max sucking weight:1200kg

3.1.3. glass size:3600mm× 2500mm

3.1.4. Outer dimension:2500 × 1500 × 1700mm

3.1.5.motor power:0.37KW

3.1.6.Power:AC380V,50Hz

3.1.7.Air source:Pressure 0.5~0. 8Mpa, flow capacity 6.3L/min

3.1.8.Weight:1200Kg

3.2Transitional conveyor

3.2.1.Conveying speed:0.25~5m/min

3.2.2. Speed control method: frequency conversion

3.2.3.Conveyor motor power: 1.1KW

3.2.4.Outer dimension:2500 X 1600 X 810mm

3.2.5.Power:AC380V,50Hz, pressure :0.5-0.8mpa

3.2.6. Weight: 1100Kg

4.1. Automatic PVB Putting Machine

three-volume of PVB film automatic transposition independent by motor control,the power of the motor is 0.75 kw.

4.1. Quantity of PVB film to hold: 3 rolls

4.2.Rotation pattern of PVB film : manual

4.3. Outer dimension: 2000×3920×2400mm

4.4. Table height of roller: 860mm

4.5. Weight: 680Kg

3.Pre-heating and pre-press machine

The roller press is used for flat and laminated glass and multilayer combination of bulletproof glass consisting of top segment,prepress,heating up,final press and off-loading section. At the same time ,It’s able to instead of the pre-pressing and heating-pressing machine of the hollow glass production line .the machin has PLC touch cabinet and one –button start.,adjust the pressure from 0 to 0.6mpa according to the glass thickness and area.

5.1. Technical parameters

5.1.1. Max glass width: 2500mm

5.1.2. Min glass width: 300mm

5.1.3. test and adjust the glass thickness full-autimatically

5.1.4. gear box is made of 10mm steel plate.

5.1.5. Processed glass thickness: 4~65mm

5.1.6. Stage level of roller: 860mm

5.1.7.Conveying speed:0~400m/min (frequency conversion ajustable )

5.1.8. there’s two sections of the heating part ,the total height is 4.6m,each section is 2.3m. there are 60 infrared heating elements and stainless steel reflector panel,the heating room is covered with Silicon cotton and protect by galvanized iron sheets .

5.1.9. Total power: 63KW, heating power:62kw, transmission power:1.1kw

5.1.10.Power:AC380V,50Hz

5.1.11. Speed control method: frequency conversion

5.1.12. Weight: 4500Kg

5.2. Structural features

5.2.1. The outer cover is cold plate painting.

5.2.2. The promotion structure is made of screw ,linear shaft ,angular tooth ,electrical cylinder

5.2.3. Structure of roller :top grade rubber roller of high temperature and aging resistant

4.Glass autoclave

The infrared autoclave fits to manufacture curved and flat laminated glass ---architectural laminated glass, automative glass and bullet proof glass. The installed power of infrared autoclave is 50% less than existing autoclave and its energy-saving 30-40% .We also offer following glass laminating line machines: glass loading、 glass off-loading、glass washing and drying, assembly room,over-head vacaum lift,transfer unit and positioning station , IR preheat oven and presser, autoclave-car and PVB interlayers for laminated glass.

The infared autoclave adopt the design of a new train of thought, namely,make use of the natural forces and function of complex ways, greatly reducing the installation power and create the conditions for highly efficient heating method ..

The central technology of Autoclave is the circulatory system and match heating system, which used the world's first natural cycle structure, heating and pressure power even cooling power and cycle power coincide, so that air can be natural circulation when heating and cooling; wavelength matches the heating system in accordance with the principle of selection of a specific wavelength of infrared transparent gold-plated heating tube ,can be reached the high efficiency of heating and absorption of glass.

Furthermore, infrared autoclave cooling system and control system of technological innovation: the cooling system uses hot-dip galvanizing finned tube seamless steel pipe,with descaling and anti-scaling technology, non-scaling and does not rust; control system adopted optimized process curve, the exhaust from working to the end is one-touch, high degree of automation, to avoid the impact of the quality by the uneven level of the operator. Practicable technical won’t make fire for the autoclave without air steam

Specifically,there’s some merits as followings

1.low power,high efficiency,and noticeable energy saving

The working time of Infared autoclave is less than or basically the same as the traditional autoclave, but only half of its installation power or even lower. Autoclave of dia2650 * 5500mm only 86KW, Autoclave of dia 2650 * 6000mm only 92KW, dia2850 * 6000mm only 102KW, dia3000 * 8000mm only 144KW. compared with the traditional autoclave ,The installation of the infared one is reduced nearly 50%,more than 30-40% of energy saving,

2.appropriate circulation ,temperature uniformity. The highest temperature is always controlled at less than 130 ℃

3.PLC+ touch screen system and one-touch complete, High automation degree.

Cooling system equiped with descaling and anti-scaling technology, non-scaling and does not rust

Practicable technical won’t catch fire for the autoclave without air steam

6. no noise and no oil pollution, so that to achieve clean and civilized production workshop

The quality of Autoclave depends on four aspects:

1. the quality (good or bad) of autoclave body itself: there’s no problem with the pressure of the body, the key is the quality of autoclave door flange and solid and smart of opening the door or not. Ours is a steel forging of the flange which is the best in china, the door device (as the picture shows ) is not only solid, and easy to adjust, although 1 ton heavier than 1 ton of others, but easy to use, long-term deformation. Adjustment easily switches by a person. Many autoclave door of other manufacturers is deformation after a period of time, brought many troubles to the customers.

2. technology of autoclave is advanced or not: depend on two aspects, first, energy-saving or not, the second is whether the uniform temperature.

3. water-cooled system and the life of the heating tube: Cooling water pipe leaks and heating tube is short-life, they are a common problem in many autoclave. the cooling system of infrared autoclave adopts finned tube seamless steel pipe and hot-dip zinc processing, non-scaling and does not rust,the life is several times more than ordinary zinc pipe ; infrared heating tube is gold-plated tube, it is not only high efficient, but also long life, there are several times more than the ordinary white quartz heating tube.

4 . Control system: The good control system must be the craft optimization product qualified rate is high, simultaneously the automaticity is high, the operation is simple, cannot operate each kind of pressed key's control system frequently. The infrared autoclave’s control system unified key starts, the entire journey automation, saves the person convenient qualified rate to be high. Has avoided the operators level irregularly to the product quality influence. The practical and feasible technological means will cause the autoclavenot to need to steam spatially will not catch fire

Main configuration of the equipment

PLC control system 1 set

Autoclave body 1 piece

Autoclave door 1 set

Motor 2 sets

Heater 1 set

Cooler 1 set

Electric control cabinet 1 set

Safety valve 2 pieces

Pressure gauge 1 piece

Spare parts (tool) 1 set

Main technical parameters of the equipment

No. | Content | Technical parameter |

1 | Design pressure | 1.5MPa |

2 | Working pressure | 1.2-1.3 MPa |

3 | Design temperature | 150℃ |

4 | Working temperature | 120-130℃ |

5 | Working medium | Compressed air |

6 | Popping pressure of safety valve | 1.4 MPa |

7 | 102KW | |

9 | Heating method | a specific wavelength of transparent gold-plated infrared heating tube |

10 | Temperature and pressure control method | PLC |

11 | Length | 6000mm |

12 | 2650mm |

*20years factory production experience*3 years machine warranty

*156 exported country experience

*20000 square meters Glass machine&upvc windows machine factory

*Shandong Eworld Machine Co., Ltd.

Shandong Eworld Machine Co., Ltd. is one of the famous and big manufacturers of glass equipment, windows equipment, CNC equipment.

Since its inception in 2002, and after many years of development and growth, the company is now playing a leading role in glass machinery and windows door machine inChina Eworld group has 2 factories, which are located in Jinan City. Advanced products, exquisite techniques, solid working, and cordial services

About glass deep processing machines, we are professional and have full set certificates.For every glass cutting machine, we have

serious quality control for every machine and every parts before it leaves our factory.

We went to many exhibitions in China to expand our reputation.

Welcome to visit our factory!If you have plan to come to China and see our machines, please contact us at least 15 days in advance

then we can arrange our

schedule and arrange to treat you.

No matter which transport method you choose, we will pick up you.

If you have any questions, please feel free to contact us.

24*7, we always be here !

FAQ

Question:Are you manufacture?

Answer:Yes,we are the professional manufacture which have more than 5 workshops.

Question: How about the service ?

Answer:

1).reply it at once if from Ali-trademanager,if by email,it reply it within 12 hour

2).deliver max. days within 15 days

3).24 hours for after -sale serive

4).more than 12 years experience in this kind machine field

5).fluent english ,communication barrier free

Question:What’s the guarantee ?

Answer:

1).Our guarantee for 18 months.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).2 year quality guaranty for the machine (excluding the consumables)

5).We will provide the consumable parts at an agency price

6).24 hours on line service each day, free technical support.

Q: Do you provide equipment operation training?

Answer:Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. Allof our engineers have passport.

Question:if our price is higher than another company or factories ?

Answer:please check, what is is the different of the machine parts ,service and guarantee,especially the machine inner electric parts,sometimes, if machines have breakdown, the most reason is the machine inner electric parts problem, but we use the famous andreliable parts for the machines inside.

Question:How long is the delivery time ?

Answer:For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients specific requirements, it would be 15 to 30 days.

Question: What is the payment ?

Answer:Any payment method you want,such as L/C,T/T,D/P,West-union and so on.