WhatsApp: +8615665767071 Email: info@eworldmachine.com

Views: 0 Author: Site Editor Publish Time: 2026-01-08 Origin: Site

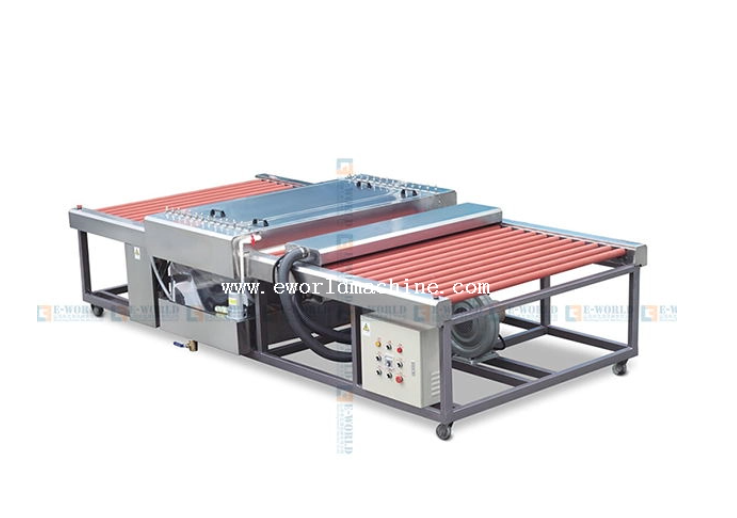

A Horizontal Glass Washing Machine is a game-changer for anyone working with flat glass. Whether you produce double glazing, screen-printed panels, or delicate Low-E glass, this Glass Washing Machine delivers spotless, streak-free results every time. By automating pre-wash, main wash, rinsing, and drying, it saves time, reduces labor, and boosts production efficiency. In this guide, we’ll explore how a horizontal glass washing machine works, its benefits, and why it’s essential for flat glass manufacturing, electronics, and architectural applications.

A horizontal glass washing machine is a device used to clean flat glass efficiently. It’s built to handle multiple sheets at a time while ensuring every surface is spotless. Unlike vertical machines, it moves glass horizontally through the cleaning stages rather than vertically.

Horizontal machines are ideal when speed, uniform cleaning, and automation matter most. They reduce manual labor and provide consistent results for large-scale operations.

These machines combine several sections to clean and dry glass effectively. Here’s a quick breakdown:

| Section | Function | Key Features |

|---|---|---|

| In-feed Conveyor | Moves glass into the machine | Adjustable speed, gentle handling |

| Pre-Washing | Removes dust and debris | High-pressure nozzles, water or cleaning solution |

| Main Washing | Deep cleaning | Multi-directional brushes, sponge rollers, solution circulation |

| Rinsing | Eliminates leftover cleaning agents | Multi-stage water jets, flow & pressure control |

| Drying | Removes water marks | Hot air blowers, adjustable air knives |

| Control System | Monitors & automates | PLC, sensors, automated alerts |

Each component works in sequence to make sure the glass comes out completely clean without streaks or scratches.

The cleaning process is straightforward but highly efficient:

Pre-Wash – Glass enters the machine and gets sprayed by high-pressure water or cleaning solution. Large particles are removed early.

Main Wash – Brushes and sponge rollers scrub the surface from multiple angles. Cleaning solution circulates continuously.

Rinse – Multi-stage water jets flush off any remaining dirt or solution. Flow and pressure are adjusted across the glass width.

Dry – Hot air blowers or air knives dry the glass evenly. Adjustable airflow prevents water marks or warping.

It’s important to control brush speed, water pressure, and solution flow evenly. Uneven settings can leave spots or cause damage.

Modern machines, like the Automatic Horizontal Screen Printing Glass Washing Machine, handle all these steps automatically. They can clean glass sheets of various sizes and thicknesses while keeping everything consistent.

Cleaning glass by hand takes ages. It’s slow, tiring, and easy to miss spots. A horizontal glass washing machine, however, handles multiple sheets per cycle. It moves glass through pre-wash, main wash, rinse, and drying sections automatically.

Cleans several sheets at once.

Reduces manual labor drastically.

Speeds up production lines and increases throughput.

| Method | Sheets per Hour | Labor Effort |

|---|---|---|

| Manual Cleaning | 10–20 | High |

| Horizontal Glass Washer | 80–150 | Low |

Machines maintain pace consistently. It keeps production steady and predictable.

One of the biggest perks is spotless, streak-free glass every time. Multi-directional brushes and sponge rollers scrub glass evenly. Hot air or air knives finish drying perfectly. Every sheet comes out uniform, no missed spots, no scratches.

Low-E coated glass

Screen-printed panels

Tempered or laminated glass

Machines save money long-term. You don’t need as many operators or cleaning supplies. Even small savings add up on high-volume production lines.

Fewer labor hours required.

Lower water and chemical usage.

Glass lasts longer thanks to gentle cleaning.

Cleaning large or heavy glass manually is risky. Breakage can cause serious injuries. A horizontal glass washer keeps operators safe. It’s enclosed, so people avoid direct contact with glass or chemicals.

Minimal risk of cuts or accidents.

Reduced chemical exposure.

Easier handling for operators, less strain.

Machines aren’t limited to one type of glass. They handle:

Various sizes and thicknesses

Flat and slightly curved panels

Screen-printed or coated glass

They integrate easily into double glazing lines or other production setups, so you don’t need different machines for different jobs.

Automation is a big game-changer. Operators just load glass, set parameters, and let the machine do the rest. It keeps production running smooth without constant monitoring.

PLC controls with adjustable brush speed

Notifications when cleaning completes

Reduced human supervision and fatigue

Modern machines help reduce environmental impact. They recycle water and use chemicals efficiently. Energy-efficient motors keep power consumption low.

Reusable water systems

Minimal chemical waste

Efficient heating and airflow

Horizontal glass washing machines aren’t limited to one type of glass. They are highly versatile and find use across multiple industries. They make cleaning fast, consistent, and safe, whether you’re handling large sheets or delicate panels.

In flat glass production, it’s crucial that each sheet is spotless before cutting, tempering, or further processing. These machines remove dust, oil, and other contaminants efficiently, ensuring optical clarity and consistent quality. By automating this process, manufacturers save time and reduce defects caused by manual cleaning.

For double glazing, clean glass is essential to achieve perfect insulation and sealing. Even tiny particles can create defects or reduce adhesion between layers. Horizontal glass washers provide uniform cleaning, improving production speed while reducing rejects. They help operators maintain high-quality standards across entire production lines.

Screen-printed or coated glass surfaces need extra care. Horizontal washers use multi-directional brushes and soft sponge rollers to remove ink, dust, and grease without scratching or damaging coatings. This makes them perfect for Low-E, reflective, or specialty coated glass. Every sheet comes out even and consistent, which is critical for decorative and functional applications.

Large panels for construction or industrial use can be difficult to clean manually. Horizontal washing machines handle wide sheets with ease, removing dirt, debris, and watermarks. Clean glass ensures safety, improves visual clarity, and prepares panels for laminating, tempering, or installation, helping construction projects run smoothly.

Precision and surface perfection are a must in electronics. Display panels, touch screens, and other thin glass components require flawless cleaning. Horizontal washers remove microscopic dust, fingerprints, and smudges efficiently. They support high-speed production lines while keeping delicate glass intact, making them ideal for mobile phone or electronic device manufacturing.

| Industry | Glass Type | Why Use Horizontal Washer |

|---|---|---|

| Flat glass | Large sheets | Uniform cleaning before cutting or tempering |

| Double glazing | Insulated units | Improves sealing, reduces defects |

| Screen printing | Printed panels | Protects coatings, removes ink residue |

| Architectural | Building panels | Prepares for laminating or installation |

| Electronics | Phone or display glass | Eliminates dust, ensures surface perfection |

Selecting a horizontal glass washing machine can be tricky if you don’t know what to look for. Different machines handle different glass types, speeds, and cleaning methods. Picking the right one ensures smooth production, consistent quality, and long-term savings.

Glass thickness and size matter. Some machines handle thin glass as small as phone panels, while others manage large sheets up to 1600 mm wide. Production speed is another factor—machines are rated in meters per minute or sheets per hour, and you want one that matches your output goals.

The cleaning method is also important. Brushes, sponge rollers, or a combination are available. Brushes scrub dirt effectively, while sponge rollers provide gentle cleaning for coated or delicate surfaces. Drying technology varies too. Hot air blowers dry quickly, while air knives provide uniform, streak-free drying.

Automation level is key for efficiency. Machines with PLC controls allow adjustable brush speed, water flow, and cleaning cycles. Sensors and alerts reduce manual supervision, so operators can focus on other tasks.

| Feature | Pros | Best Use |

|---|---|---|

| Brushes | Deep cleaning | Standard flat glass |

| Sponge Rollers | Gentle, scratch-free | Coated, Low-E glass |

| Hot Air Blower | Fast drying | Large panels |

| Air Knife | Streak-free drying | Thin or delicate glass |

By matching glass type, speed, cleaning method, and automation, you can choose a machine that fits your line perfectly.

Even the best machine needs care. Brushes, rollers, and nozzles wear over time, so routine inspection is critical. They should be cleaned and replaced as needed to maintain performance. Alignment checks, motor function tests, and sensor calibration help prevent uneven cleaning or downtime.

Choosing durable materials matters too. Stainless steel frames resist corrosion, and high-quality polymers in rollers and brushes last longer. A well-maintained machine runs consistently, delivers uniform cleaning, and avoids costly repairs.

Maintenance Checklist:

Inspect brushes and sponge rollers weekly.

Clean and unclog nozzles regularly.

Check alignment, sensors, and motors monthly.

Replace worn parts with high-quality components.

Ready to take your glass production to the next level? A horizontal glass washing machine makes cleaning faster, safer, and more precise than ever. Whether you handle large construction panels or delicate electronics glass, it ensures every sheet comes out perfect, reducing errors and boosting efficiency.

At Shandong Eworld Machine Co., Ltd., we specialize in advanced solutions for flat glass cleaning. Explore our range of automatic horizontal glass washers today and see how they can transform your workflow, save labor, and deliver consistent, high-quality results every single time.

A: Yes, they can. Machines with sponge rollers or gentle multi-directional brushes clean delicate surfaces like Low-E or screen-printed glass without scratches.

A: Horizontal machines move glass sheets horizontally through cleaning stages, while vertical machines move glass upright. Horizontal models are ideal for high-speed, large-scale production.

A: Space depends on model and glass size, typically requiring enough room for in-feed, cleaning sections, drying, and operator access, often several meters in length and width.

A: Automation controls brush speed, water flow, and drying. Sensors and PLCs reduce supervision, ensure uniform cleaning, and increase throughput.

A: Yes, they are enclosed, preventing direct contact with cleaning solutions, reducing chemical exposure, and minimizing risk to operators.